What did you do today? Cobba's rebuild

Moderators: trixynut, Mincehead, dicky, phuk72, Jak, Kevtrx849

-

lenny

- TRX-Enthusiast

- Posts: 134

- Joined: Tue May 08, 2007 1:24 pm

- Location: far north queensland

Re: What did you do today? Cobba's rebuild

Buy some copper sheet of required thickness, trace oem gasket onto sheet with bigger bore size. Jigsaw, drill, file to shape taking care to not bend or distort sheet too much. Heat gasket and drop into cold water. Clean off scale with scotchbrite pad. Fit using high temp silicone (thin film). Retorque head after several hundred kays. I have made head gaskets for some pretty wild motors this way and never had a problem. Composite head gaskets are used because they are cheap, not necessarily better. It has never made sense to me to insulate the head from the barrel.

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Re: What did you do today? Cobba's rebuild

The issue with the Trx and copper head gaskets running a 12:1 + compression is the head is lifting ever so much. There is only 6 bolts to compress the chamber area and it was only designed to deal with 9.5:1 on the xtz750..

Great concept copper gaskets and works fine on std and modded trx's just not practical once you push the envelope on comp ratios from 12:1.

The more I chat with those who have raced Trx only confirms this.

I've already got a CAD outlay made of the Trx head gasket so all my gaskets are presision made and laser cut.

I'll have to dial in cam timing once again even though 0.1mm thinner will be about 1/2 degree but It all makes a difference.

The exhaust cam was 3* from Kent spec using the std cam sprockets so dialing my centre back from 112* to the spec 109* gave me more overlap.

I wonder if this be the reason I found a little less torque figures than a few of the other guys and their rebuilds but I found more horsepower.???

We all have principlely the same valve-head/cam/exhaust systems just slightly different cam timing.

So even though I'm looking at 12.5:1 static compression my true engine compression will be down a touch due to the overlap and leakage .

I wouldn't be suprised if the Nuda 900 with its 13:1 static compression runs more overlap or steeper ramp and brings the a real motor compression ratio down.

Great concept copper gaskets and works fine on std and modded trx's just not practical once you push the envelope on comp ratios from 12:1.

The more I chat with those who have raced Trx only confirms this.

I've already got a CAD outlay made of the Trx head gasket so all my gaskets are presision made and laser cut.

I'll have to dial in cam timing once again even though 0.1mm thinner will be about 1/2 degree but It all makes a difference.

The exhaust cam was 3* from Kent spec using the std cam sprockets so dialing my centre back from 112* to the spec 109* gave me more overlap.

I wonder if this be the reason I found a little less torque figures than a few of the other guys and their rebuilds but I found more horsepower.???

We all have principlely the same valve-head/cam/exhaust systems just slightly different cam timing.

So even though I'm looking at 12.5:1 static compression my true engine compression will be down a touch due to the overlap and leakage .

I wouldn't be suprised if the Nuda 900 with its 13:1 static compression runs more overlap or steeper ramp and brings the a real motor compression ratio down.

Last edited by cobbadiggabuddyblooo on Tue Sep 29, 2015 1:40 pm, edited 4 times in total.

laughter is the best medicine

- Rod.s

- Site Sponsor

- Posts: 1404

- Joined: Sun Apr 25, 2010 11:01 am

- Location: Brisbane, Australia

Re: What did you do today? Cobba's rebuild

Mate as we have discussed many times over the years, it all academic, those that know do, those that don't guesscobbadiggabuddyblooo wrote:The issue with the Trx and copper head gaskets running a 12:1 + compression is the head is lifting ever so much. There is only 6 bolts to compress the chamber area and it was only designed to deal with 9.5:1 on the xtz750..

Great concept copper gaskets and works fine on std and modded trx's just not practical once you push the envelope on comp ratios up to 12:1.

The more I chat with those who have raced Trx only confirms this.

I've already got a CAD outlay made of the Trx head gasket so all my gaskets are presision made and laser cut.

I'll have to dial in cam timing once again even though 0.1mm thinner will be about 1/2 degree but It all makes a difference.

The exhaust cam was 3* retarded from std using the std cam sprockets so dialing my centre back from 112* to the spec 109* gave me more overlap.

This may be the reason I found a little less torque figures than a few of the other guys and their rebuilds but I found more horsepower.???

We all have principlely the same valve-head/cam/exhaust systems just slightly different cam timing.

So even though I'm looking at 12.5:1 static compression my true engine compression will be down a touch due to the overlap and leakage .

I wouldn't be suprised if the Nuda 900 with its 13:1 static compression runs more overlap or steeper ramp and brings the a real motor compression ratio down.

If it's not made in China, it's a fake!

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Re: What did you do today? Cobba's rebuild

And those that want to learn, ask questions.

What I learn through this motor excersize may help many on their own quest.

There are so many factors that come into play as you have pointed out on a number of our chats and appreciate the guidance.

Pistons read well with good colouring and deposits all around the edges and behind the valve reliefs.

No sign of detonation but this may be counteracted by the overlap allowing for a lower dynamic compression.

There is an optimum point on all elements and yes you can never get anything perfect as there are so many variables.

Maybe pushing past 12:1 compression may be out of the optimum for the cam timing and lobe separation angle and pushing things further may actually be robbing me of power???

I'm currently waiting on a couple of responses from those who do know to draw on some of their wisdom.

Rome was not built in a day..

Hang on

broken record... I've gone around this before... maybe I should read some of my previous posts...

broken record... I've gone around this before... maybe I should read some of my previous posts...

What I learn through this motor excersize may help many on their own quest.

There are so many factors that come into play as you have pointed out on a number of our chats and appreciate the guidance.

Pistons read well with good colouring and deposits all around the edges and behind the valve reliefs.

No sign of detonation but this may be counteracted by the overlap allowing for a lower dynamic compression.

There is an optimum point on all elements and yes you can never get anything perfect as there are so many variables.

Maybe pushing past 12:1 compression may be out of the optimum for the cam timing and lobe separation angle and pushing things further may actually be robbing me of power???

I'm currently waiting on a couple of responses from those who do know to draw on some of their wisdom.

Rome was not built in a day..

Hang on

Last edited by cobbadiggabuddyblooo on Thu Oct 08, 2015 2:39 pm, edited 1 time in total.

laughter is the best medicine

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Re: What did you do today? Cobba's rebuild

Ok after climbing out of my dark little hole of late...

Picked up the pistons after having the skirts ceramic coated once again.

Bores where honed to the required 0.004" clearance and then returned to Peter at Competition coatings.

He then ran a final hone to plateau the finish and cleaned up the taper on the bottom edge to prevent any scoring of the bottom of the piston skirts.

Why the plateau hone????

With the new rings designs and synthetic oils the hone doesn't need to be so coarse and helps for the rings to bed in faster.

He then sat down and explained his set up for taking material off MLS gaskets to suit the oversize bore and showed me an example on a speedway bike piston/barrel gasket he had just finished.

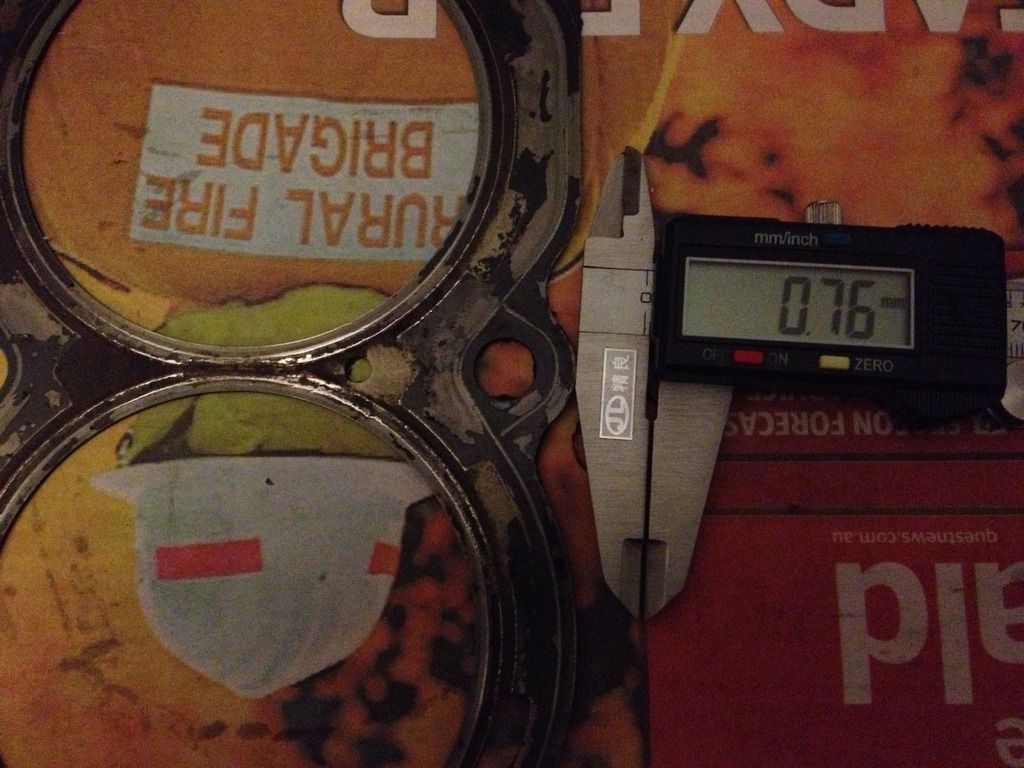

So the photo above is for reference of a std TRX MLS gasket.

Compressed thickness was measured at 0.76mm , measured around the edges .

Just waiting now on the new rings and lock wires from Arias and I can put things back together once again.

In the mean time, I have 3 old std trx MLS gaskets in the garage to practise on to remove what I need for the oversize bores.

Last edited by cobbadiggabuddyblooo on Wed Oct 28, 2015 12:20 pm, edited 1 time in total.

laughter is the best medicine

- Rod.s

- Site Sponsor

- Posts: 1404

- Joined: Sun Apr 25, 2010 11:01 am

- Location: Brisbane, Australia

Re: What did you do today? Cobba's rebuild

Great work mate  loving the progress on the new engines "evolution"

loving the progress on the new engines "evolution"

If it's not made in China, it's a fake!

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Re: What did you do today? Cobba's rebuild

Below is a photo of a new std gasket clearly showing the 3 steel layers in it's construction.

The fire ring measured in at 1.2mm thick and 1mm on the outer edges on the rivets of the gasket.

Looking for an answer for the true compressed thicknesss I found some say

To measure at the rivets

So I contacted John at gasket solutions and he advised me on how to get the correct measurement.

The 3 sections are made of spring steel. The raised sections compress and if any lift from the head, the 2 outer layer that have the raised stamp will spring out to help hold the seal. The outside sheets have a coating to aid in sealing it all too.

He suggested I measure the outer sheet on a flat section away from any stamping and measure the middle sheet. The middle shim sheet is there to pack it all out to the desired gasket thickness.

So measurements where 2.2mm for each outer layer and 3.4 mm for the centre shim.

This gives pretty dammed close to the 0.76 mm...

The fire ring measured in at 1.2mm thick and 1mm on the outer edges on the rivets of the gasket.

Looking for an answer for the true compressed thicknesss I found some say

To measure at the rivets

So I contacted John at gasket solutions and he advised me on how to get the correct measurement.

The 3 sections are made of spring steel. The raised sections compress and if any lift from the head, the 2 outer layer that have the raised stamp will spring out to help hold the seal. The outside sheets have a coating to aid in sealing it all too.

He suggested I measure the outer sheet on a flat section away from any stamping and measure the middle sheet. The middle shim sheet is there to pack it all out to the desired gasket thickness.

So measurements where 2.2mm for each outer layer and 3.4 mm for the centre shim.

This gives pretty dammed close to the 0.76 mm...

Last edited by cobbadiggabuddyblooo on Wed Jan 20, 2016 3:33 pm, edited 3 times in total.

laughter is the best medicine

- Mincehead

- TRX-Enthusiast

- Posts: 6345

- Joined: Sun Jan 25, 2009 1:40 pm

- Location: West Sussex

Re: What did you do today? Cobba's rebuild

Mate how thick is that fetching throw on the sofa? GOOD MAN for working on bike stuff in comfort, I do the same, much to the annoyance of Ness.

LOUD PIPES SAVE LIVES

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Re: What did you do today? Cobba's rebuild

It's the bed cover over the bike... Janet couldn't find the glad wrap either the other day as it's in the garage too.

wrap up and seal all my bits n pieces including the bottom end of the motor...

Handy info compiled from Quickdraw, Dandy and Sanddunes

CC OF STD PISTON, COMBUSTION CHAMBER and GASKET CC

http://www.trx850.com/phpBB_forum/viewt ... =6&t=10078

wrap up and seal all my bits n pieces including the bottom end of the motor...

Handy info compiled from Quickdraw, Dandy and Sanddunes

CC OF STD PISTON, COMBUSTION CHAMBER and GASKET CC

http://www.trx850.com/phpBB_forum/viewt ... =6&t=10078

laughter is the best medicine

-

lenny

- TRX-Enthusiast

- Posts: 134

- Joined: Tue May 08, 2007 1:24 pm

- Location: far north queensland

Re: What did you do today? Cobba's rebuild

Hey Cobba, I think you could have a lot of fun with a good engine simulator program. I'm not talking about those crappy "desktop dyno" things, but a real simulator based on gas and thermo dynamics. Probably the two most advanced available to the public are Ricardo Wave and Lotus Engine Simulator. They have been used to develop engines as varied as locomotive and submarine engines down to model aircraft and drone engines. I am more familiar with L.E.S. as its a bit easier to get into and has some really cool features. To build an engine model that will generate a very accurate power and torque curve requires a LOT of data,much of it probably only available from the manufacturers development program, but that's not the true value for us. Using even a basic TRX model you can generate a power and torque curve and then by changing any of the parameters (port length or volume, compression ratio, exhaust dimensions, valve timing,anything you want) and rerunning the sim and seeing how it affects the curves is a great learning tool. Being able to watch the colour coded pressure and vacuum waves bounce up and down the inlet and exhaust systems in slow motion is magic. You can learn more about the way engines REALLY work in a couple of days than years of reading books. And its fun. L.E.S is free for the single cylinder version but that's no consequence unless you want to design a two into one or linked system.I have the twin cylinder version which used to also be free but alas free no more. Here is a link to a paper from Ducati on how they used a sim to develop the two into one system for the 999. This is relevant to the trx as it has the same piston phasing as a 90' v twin and shows how a symmetrical 2/1 will never work very well on an assymetric motor like the TRX or Ducati. https://docs.google.com/viewer?a=v&pid= ... h&hl=en_US

You may also find some other very trick programs on the L.E.S. website that interest you.

You may also find some other very trick programs on the L.E.S. website that interest you.

- dandywarhol

- Site Sponsor

- Posts: 1639

- Joined: Fri Nov 24, 2006 12:56 pm

- Location: Edinburgh, Scotland

Re: What did you do today? Cobba's rebuild

That's an interesting paper Lenny - thanks. It does make you wonder just how much time is spent by the manufacturer to get a good compromise of performance over noise.

It also makes you think if the aftermarket exhaust system manufacturers (especially the cheaper ones) really know what they are doing in terms of performance gains (or losses!) I know when I changed from Carbon Can Company silencers to Akrapovic ones the difference in mid range was immense - and that was with standard downpipes (TDM900)

I recently spoke at length to the owner of MHP exhausts in the UK when investigating a system for my SZR660 and Mark certainly talked the talk - he was OCD passionate about exhaust systems and really seemed to know his stuff. They supply systems to BSB race teams, so something must be working. I thought 2 stroke exhausts were a black art until speaking to Mark!!

It also makes you think if the aftermarket exhaust system manufacturers (especially the cheaper ones) really know what they are doing in terms of performance gains (or losses!) I know when I changed from Carbon Can Company silencers to Akrapovic ones the difference in mid range was immense - and that was with standard downpipes (TDM900)

I recently spoke at length to the owner of MHP exhausts in the UK when investigating a system for my SZR660 and Mark certainly talked the talk - he was OCD passionate about exhaust systems and really seemed to know his stuff. They supply systems to BSB race teams, so something must be working. I thought 2 stroke exhausts were a black art until speaking to Mark!!

1996 TRX 850, blue, Ohlins 46HRCLS, Race Tech Gold Valves, 0.90 springs, Venom pipes, R6 brakes............

1974 Yamaha RD250A, Candy Blue

1998 Yamaha SZR660, blue of course

1967 Yamaha TD1C 250, Blue and white

1974 Yamaha RD250A, Candy Blue

1998 Yamaha SZR660, blue of course

1967 Yamaha TD1C 250, Blue and white

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Re: What did you do today? Cobba's rebuild

Good reading Lenny and something I can easily relate to working in the entertainment industry for 25yrs as an audio engineer/P.A. rigger.

Having a decent tuned P.A. for the task at hand to start makes all the difference, but driving it to get the most from it took years of experience..

The tuning of the cabinet to start is paramount, with volume, porting and phasing all coming in to play and then having the option to manipulate cross over points, levels and phase correlation is just like having a well tuned intake to the exhaust and having the right amps to pump it all goes without saying.

Nothing pissed me off more than a bunch of drunken punters grabbing the wedges and moving them around on the front of the stage after spending 15 minutes tuning ..

Most of the egotistical wankers prancing around on stage couldn't tell the difference but most professional muso's would.

Having drivers no longer facing where they where tuned induced phase cancellation and little hole on the stage where you may loose the top end or suddenly find bottom end frequencies resonating .

It may just be that 1 note when the kick drum is hammered and the bass player plays his top string open in the chorus, but the bass player and drummer can feel it and I can hear it through the cue wedge and see it in their body language.

A well tuned exhaust by Akra/ Over/Nojima makes all the difference and I leant that from the first system I had mad up locally. Pay peanuts, expect monkeys

Having a decent tuned P.A. for the task at hand to start makes all the difference, but driving it to get the most from it took years of experience..

The tuning of the cabinet to start is paramount, with volume, porting and phasing all coming in to play and then having the option to manipulate cross over points, levels and phase correlation is just like having a well tuned intake to the exhaust and having the right amps to pump it all goes without saying.

Nothing pissed me off more than a bunch of drunken punters grabbing the wedges and moving them around on the front of the stage after spending 15 minutes tuning ..

Most of the egotistical wankers prancing around on stage couldn't tell the difference but most professional muso's would.

Having drivers no longer facing where they where tuned induced phase cancellation and little hole on the stage where you may loose the top end or suddenly find bottom end frequencies resonating .

It may just be that 1 note when the kick drum is hammered and the bass player plays his top string open in the chorus, but the bass player and drummer can feel it and I can hear it through the cue wedge and see it in their body language.

A well tuned exhaust by Akra/ Over/Nojima makes all the difference and I leant that from the first system I had mad up locally. Pay peanuts, expect monkeys

laughter is the best medicine

- devlin

- Site Sponsor

- Posts: 745

- Joined: Tue Mar 20, 2007 7:43 am

- Location: Brisbane, Australia

Re: What did you do today? Cobba's rebuild

I don't know the full science behind it but wave energy is one of the most powerful and complicated of sciences to get right at times. It's a fascinating part of physics.

"Racing is life, everything else is just waiting" - Steve McQueen

Four wheels move the body, two wheels move the soul.

Four wheels move the body, two wheels move the soul.

- davamb

- TRX-Enthusiast

- Posts: 818

- Joined: Fri Sep 05, 2008 12:53 am

- Location: 10mins from PI

Re: What did you do today? Cobba's rebuild

So is a 2:2 or a 2:1 system likely to be a better match for a 90degree twin compared to a 2:1:2 system?

The Fourier Transform is one of the most beautiful and elegant pieces of science and mathematics.devlin wrote:I don't know the full science behind it but wave energy is one of the most powerful and complicated of sciences to get right at times. It's a fascinating part of physics.

Ride Well!

Cheers, Dave.

Cheers, Dave.

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Re: What did you do today? Cobba's rebuild

Today's fun and games began with wiring in a new ignition key with the last one damaged in the fall.

Then fitting the pistons back onto the rods with new wire locks and rings in place.

New barrel O rings and base gasket and all ready for the first piston to be slipped into the bore.

I chose No 2 by the cam galley 1st as I did this one at TDC and easier to work around the cam chain and runner.

Used my trusty home made ring compressor made from cutting a plastic strip from the back of a $2 A4 plastic ring binder and a 4" Uni clamp.

I worked no. 2 piston all the way until the piston and rings where into the bore with only a little of the piston protruding from the bottom of the bore. I then rotated the crank to allow me to fit in piston no 1. and slipped it in with no issues.

I made some small spacers and tightened down the barrels to double check my original piston deck measurement at 0.65mm with a straight edge and feeler gauge. I got the same measurement.

Remember now I've lost 0.15mm from the previous 0.9mm head gasket so I'm now at 1.4mm/ 0.056" quench/squish not 1.55mm.

( 0.65mm deck +0.76mm H/gasket ) due to thinner head gasket so that's pushed me up to 12.5 :1 static compression and no longer 12.25.

So I calculated the dynamic compression and I'm over 10 with the cams are dialled correctly and more importantly the inlet at 105*

Simple explanation why larger cams don't really work on a std compression TRX.

If I was still running the std compression ratio, The Kent cams inlet closes 16* later as the piston rises from BDC than the std TRX cam plus the larger valves will mean I loose dynamic compression.

Because the piston is rising an extra 16* before the inlet valve closes ABDC. to offset this dynamic loss a higher static compression and more overlap is used.

With the thinner head gasket, If I leave the cam and don't dial them in, both cams are retarded a touch and the inlet valve will close a little later and drop the dynamic compression just a touch so something to be mindful of. (I may need that)

So how much dynamic comp is too much and inducing detonation with kent cams???

Time will tell and the next dyno run.

But I must be getting close to optimum .

Over racing pistons ran 12.75 :1, 2mm O/S valves and V2 cam so I'm interested once the V2 cam specs appear.

This link gives a little outline on how the dynamic and static compression work together with your cam timing

TRX 850 ROD LENGTH = 124.5mm

http://www.crankshaftcoalition.com/wiki ... patibility

This 2nd link has a good map on which way is advance or retarding valve timing

http://www.starracing.com/Cam%20Lobe%20 ... lained.htm

Then fitting the pistons back onto the rods with new wire locks and rings in place.

New barrel O rings and base gasket and all ready for the first piston to be slipped into the bore.

I chose No 2 by the cam galley 1st as I did this one at TDC and easier to work around the cam chain and runner.

Used my trusty home made ring compressor made from cutting a plastic strip from the back of a $2 A4 plastic ring binder and a 4" Uni clamp.

I worked no. 2 piston all the way until the piston and rings where into the bore with only a little of the piston protruding from the bottom of the bore. I then rotated the crank to allow me to fit in piston no 1. and slipped it in with no issues.

I made some small spacers and tightened down the barrels to double check my original piston deck measurement at 0.65mm with a straight edge and feeler gauge. I got the same measurement.

Remember now I've lost 0.15mm from the previous 0.9mm head gasket so I'm now at 1.4mm/ 0.056" quench/squish not 1.55mm.

( 0.65mm deck +0.76mm H/gasket ) due to thinner head gasket so that's pushed me up to 12.5 :1 static compression and no longer 12.25.

So I calculated the dynamic compression and I'm over 10 with the cams are dialled correctly and more importantly the inlet at 105*

Simple explanation why larger cams don't really work on a std compression TRX.

If I was still running the std compression ratio, The Kent cams inlet closes 16* later as the piston rises from BDC than the std TRX cam plus the larger valves will mean I loose dynamic compression.

Because the piston is rising an extra 16* before the inlet valve closes ABDC. to offset this dynamic loss a higher static compression and more overlap is used.

With the thinner head gasket, If I leave the cam and don't dial them in, both cams are retarded a touch and the inlet valve will close a little later and drop the dynamic compression just a touch so something to be mindful of. (I may need that)

So how much dynamic comp is too much and inducing detonation with kent cams???

Time will tell and the next dyno run.

But I must be getting close to optimum .

Over racing pistons ran 12.75 :1, 2mm O/S valves and V2 cam so I'm interested once the V2 cam specs appear.

This link gives a little outline on how the dynamic and static compression work together with your cam timing

TRX 850 ROD LENGTH = 124.5mm

http://www.crankshaftcoalition.com/wiki ... patibility

This 2nd link has a good map on which way is advance or retarding valve timing

http://www.starracing.com/Cam%20Lobe%20 ... lained.htm

Last edited by cobbadiggabuddyblooo on Mon Jul 03, 2017 2:18 pm, edited 2 times in total.

laughter is the best medicine