Next mod finished was new waterproof terminal blocks fitted to the wiring harness.

I also wired the coils to draw power directly from the battery.

1,000km service with new oil and filter and checked clearances.

But my shim kit goes from 1.65 - 2.20mm and I need to get a couple of 2.25, 2.30 and 2.35mm shims just in case I need to go up on a couple of the exhaust clearances next time .

Just a slight weep of coolant from the head gasket over the last 500km with spirited riding but it's not corrupting the oil at all.

It only leaves a slight trickle the length of the barrels and the radiator level has stayed consistent and day to day riding shows no weep, and only appears as mentioned after half a tank of spirited riding .

My own fault though as didn't think about the couple of dry runs during the rebuild had work hardened the copper head gasket

I'll just remove the head again, re anneal and hylomar sealant the gasket and all will be good.The head and barrels both had a bees dick taken off them to make sure I had a clean,flat surface to start.

Be a good opportunity to just check all is well inside.

Got this task down pat

I'll finally get around to checking float height this week and in 2 minds on setting the FCr's up with flex jets

Next task at hand will be finishing off setting up the O2 sensor gauge mount and wiring this into place.

Jet kit I ordered arrived the other week so I have main fuel and air jets from 140 to 170 fuel in 2.5 increments & 180 to 220 in increments of 5.

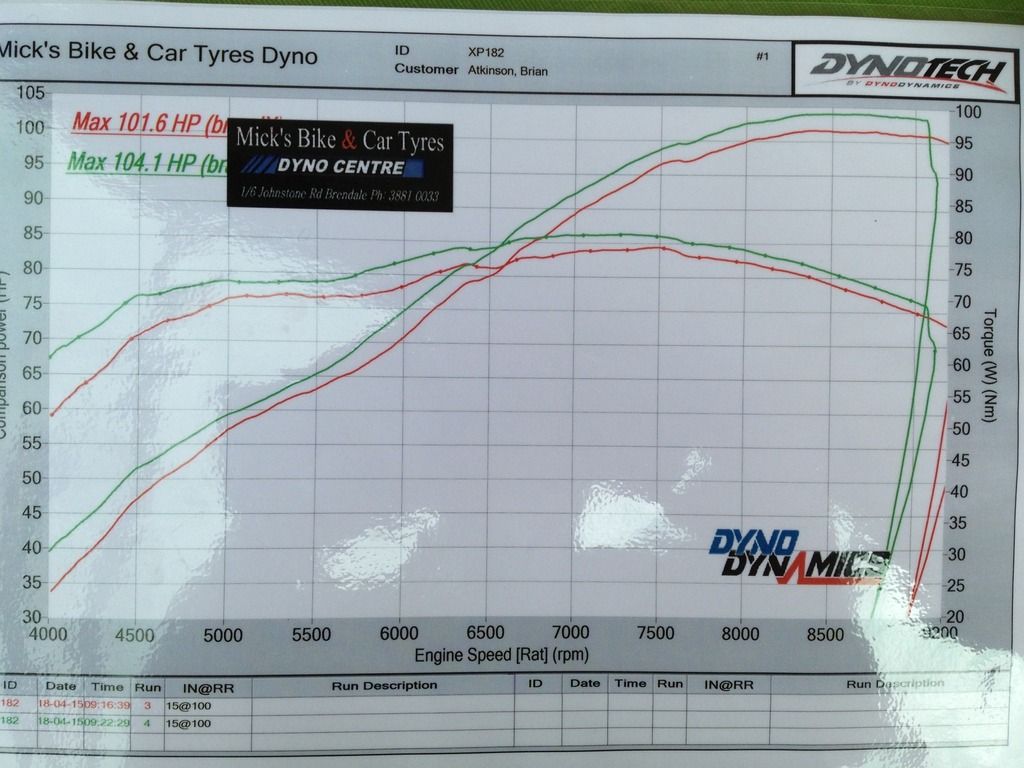

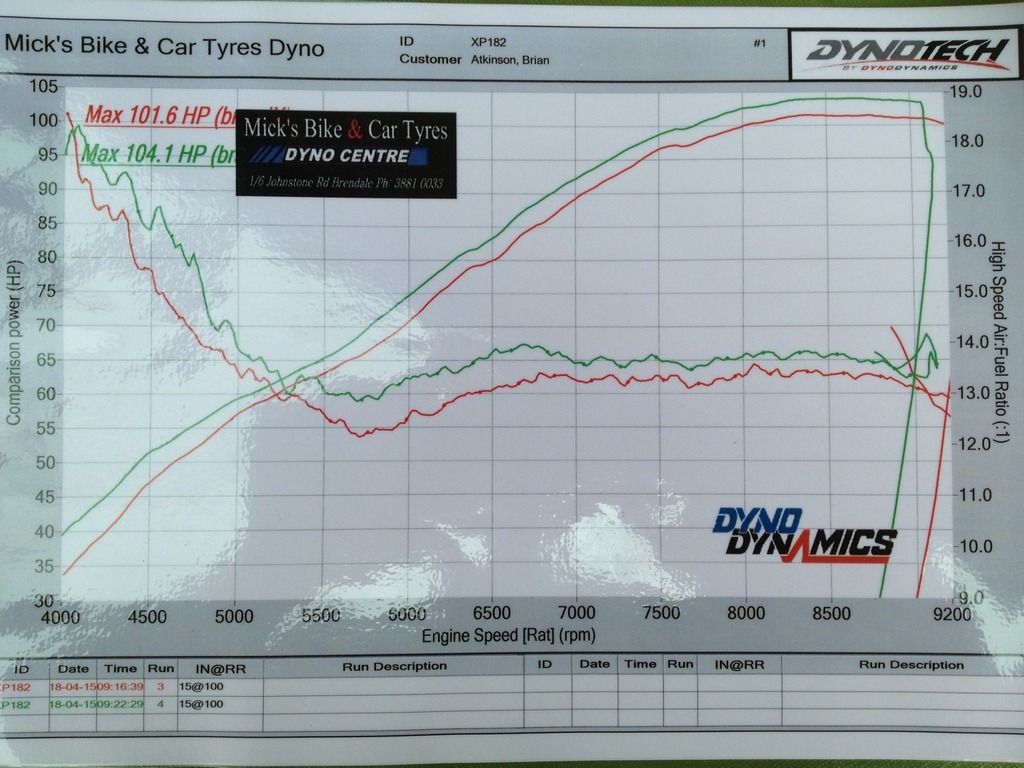

Found a guy local who does dyno runs once a month for $44 on a Saturday as a social event so I might sneak one in as a benchmark using the std FCR and default ignitech settings.

http://www.trx850.com/phpBB_forum/viewt ... t=flex+jet