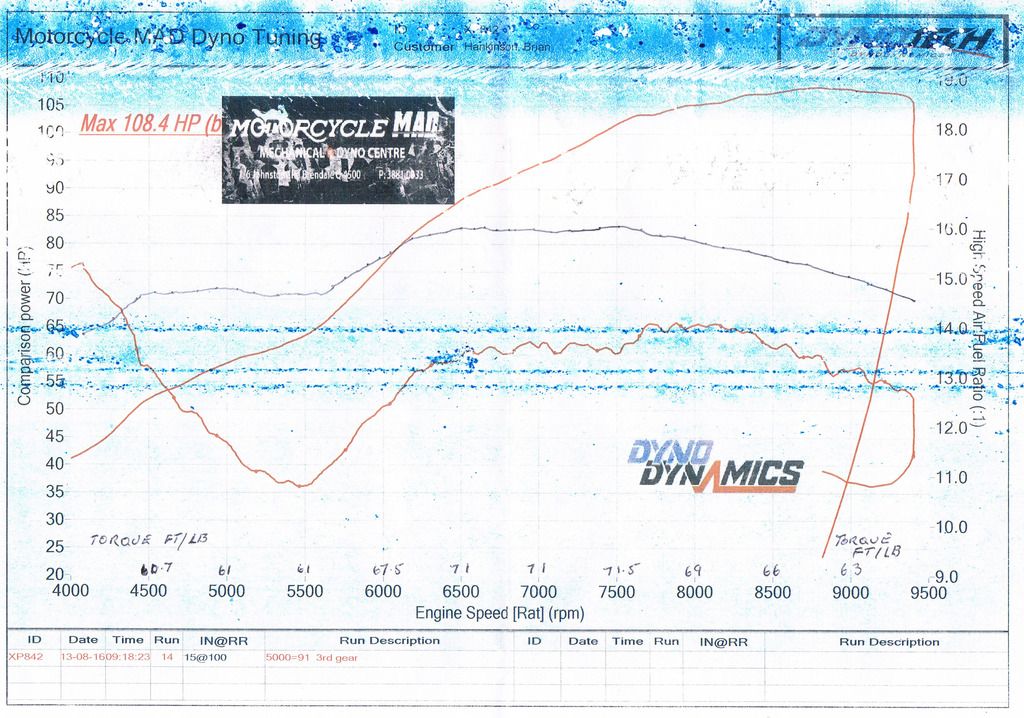

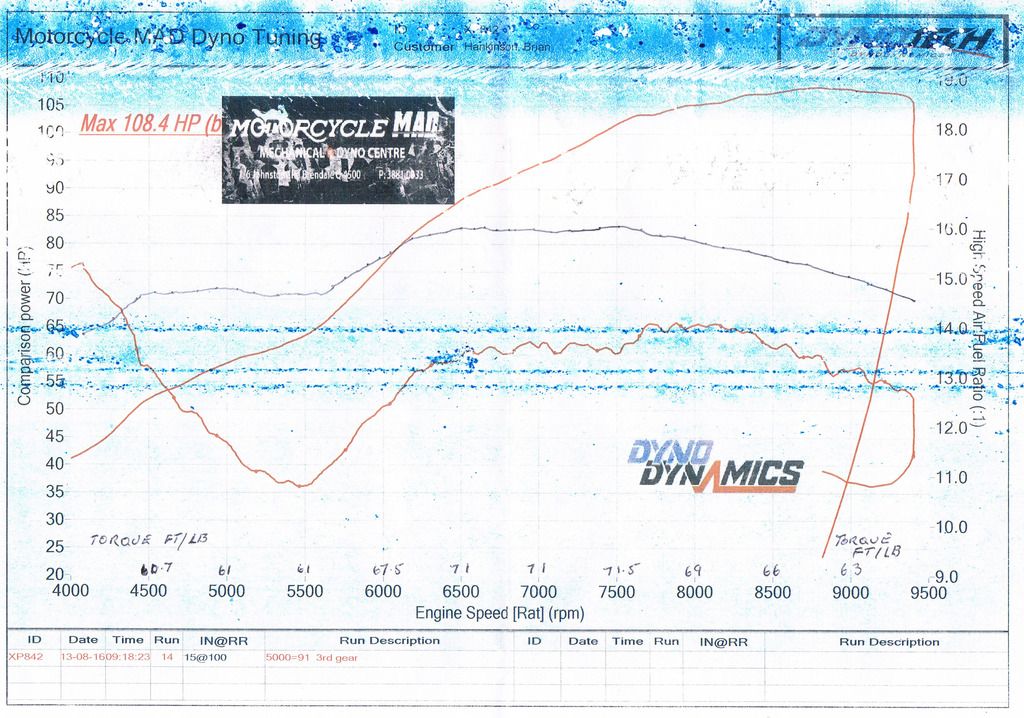

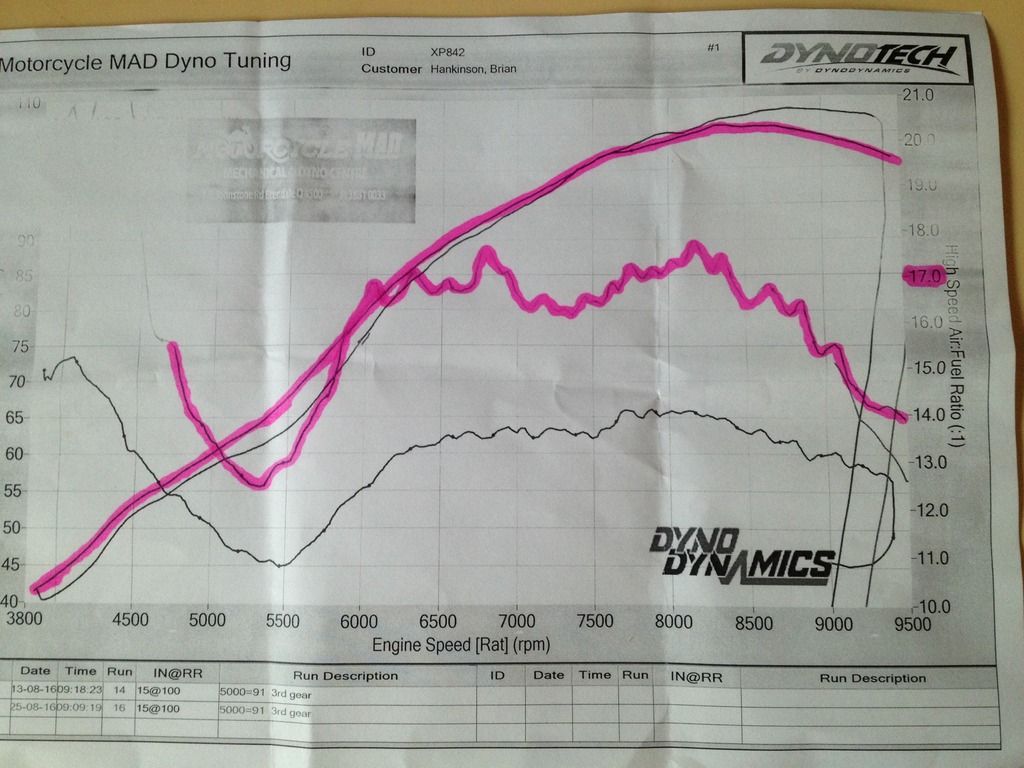

Nice day for a winter ride today.. Mid 20's and sunny.. Went over the exhaust again to reseal all the joins and fitted the 167.5 mains.

Akra system worked flawlessly and easily rideable just off idle with just a dip at 5500 and big serge again 6000 to 8500rpm.

The Nojima has different characteristics with these cams and the overlap is evident around 3200rpm and you can hear the flat slides chattering from idle to 3500rpm and come 3700rpm it's just power on tap all the way till the red light shines bright at 8500rpm. So easy to lift the front wheel in second flip flopping up the range and answered my questioning of choice of exhaust for this cam profile.

So I feel my quest if just about finally over and I'll fit the Scotts damper and take in all I've learnt in the process.

TDMR40's , Yam9 and Akra system wins hands down for a street / odd trackday TRX. Drive ability is excellent and dealing with day to day traffic is a breeze allowing you to use throttle from just above idle.

Want to build a motor to go hard on and want to keep the revs above 3500rpm , FCR's , V2 or Penner cams and a Over/Nojima style exhaust wins the gold medal from me.

Your intake and exhaust all have to work around your camshaft choice which was fairly evident by the number of changes I slowly but surely eliminated to get the desired result.

So I was on the money with the first choice of cams and exhaust, just my 12 mths down time gave me the opportunity to question things and when I purchased the 2nd set of cams, holes started to apear.

I'm sure I could have advanced the timing more around 5500rpm with the Akra system to deal with the slower burning rich mix, but that doesn't actually fix what's causing it. But god dam when you hit 6000rpm it took off like a rocket again....

Now there is a real smooth continual take up of power until 8500 and gains all the way from 4000rpm and I couldn't be happier.

Time to just dot the i's and X the tees now and just tidy up this work in progress over the past 3 years.

Photo taken today on top of the range at Mt Mee after resealing the exhaust and fitting larger 167.5 mains. 1 final dyno run to do and I'm ready to retire.