What did you do today? Cobba's rebuild

Moderators: trixynut, Mincehead, dicky, phuk72, Jak, Kevtrx849

- Stankflapper

- TRX-Enthusiast

- Posts: 1260

- Joined: Wed Jun 22, 2011 8:34 am

- Location: Australia. Land of Cold beer & Bitchy women, and fast bikes!

Re: What did you do today? Cobba's rebuild

Play Doe... Love it! bwhahahaha

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Re: What did you do today? Cobba's rebuild

Rotor puller arrived and the holes are 0.5mm out and I need to get the 3 holes ovaled to suit the job.

In the mean time I'm looking at placing the oil temp switch where I've marked the side of the sump with the black dot.

The Koso dash comes complete with oil and water temp senders oil temp senders so I figure I might as well take advantage of this function.

I'm thinking on placing it into the side of the sump and will be tidy with the alt. loom, quick shift wiring being all in within cooeee of each other.

I could have gone with the option of the oil drain plug on the bottom motor oil pan but I want to keep the magnetic drain plug I have.

The oil feeding back into the sump will be fed through an oil cooler I picked the other day to help regulate the temperature.

Another look doesn't give me much depth in the sump wall to tap a thread .

A nut on the other side is a recipe for disaster.

Any suggestions as I feel this is an ideal spot.

In the mean time I'm looking at placing the oil temp switch where I've marked the side of the sump with the black dot.

The Koso dash comes complete with oil and water temp senders oil temp senders so I figure I might as well take advantage of this function.

I'm thinking on placing it into the side of the sump and will be tidy with the alt. loom, quick shift wiring being all in within cooeee of each other.

I could have gone with the option of the oil drain plug on the bottom motor oil pan but I want to keep the magnetic drain plug I have.

The oil feeding back into the sump will be fed through an oil cooler I picked the other day to help regulate the temperature.

Another look doesn't give me much depth in the sump wall to tap a thread .

A nut on the other side is a recipe for disaster.

Any suggestions as I feel this is an ideal spot.

Last edited by cobbadiggabuddyblooo on Thu Jan 15, 2015 1:51 pm, edited 2 times in total.

laughter is the best medicine

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Re: What did you do today? Cobba's rebuild

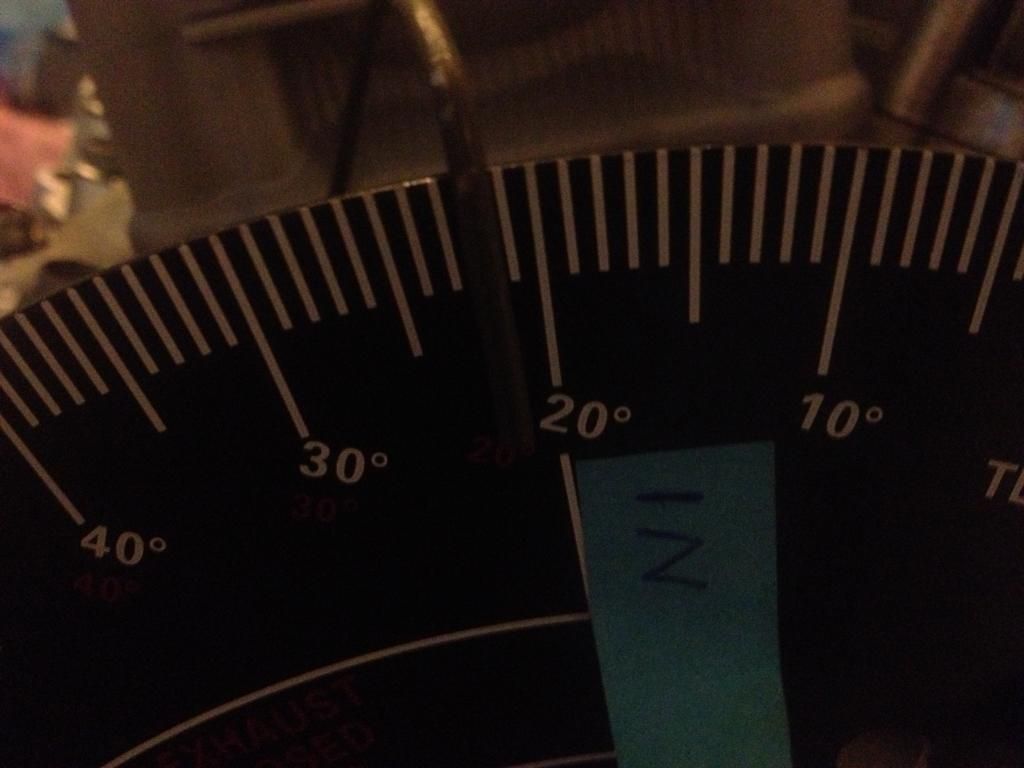

Time to check TDC via the piston stop method...

Here is the piston stop I made up for the job out of the adaptor and easy to remove the bolt so I can s use for compression testers ect. that it was intended for.

I screwed it into the spare head I have so plenty of length to do the job.

Here is the result from the piston stop method...

The only thing I noticed was I had to hold just a little pressure against the crank to get a constant and they where both the same.

If I didn't hold any pressure against the crank there could be anything up to 1 degree difference.

So there is 1 tick for Yamaha's TDC and the piston stop if done correctly..

I wonder how this little bit of movement will effect the dial indicator method as the sensitivity of the indicator doesn't allow the pressure down onto the piston like when using a bung.

Here is the piston stop I made up for the job out of the adaptor and easy to remove the bolt so I can s use for compression testers ect. that it was intended for.

I screwed it into the spare head I have so plenty of length to do the job.

Here is the result from the piston stop method...

The only thing I noticed was I had to hold just a little pressure against the crank to get a constant and they where both the same.

If I didn't hold any pressure against the crank there could be anything up to 1 degree difference.

So there is 1 tick for Yamaha's TDC and the piston stop if done correctly..

I wonder how this little bit of movement will effect the dial indicator method as the sensitivity of the indicator doesn't allow the pressure down onto the piston like when using a bung.

Last edited by cobbadiggabuddyblooo on Fri Jan 16, 2015 8:49 am, edited 3 times in total.

laughter is the best medicine

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Re: What did you do today? Cobba's rebuild

NOTE

LEAK JET for fcr's

http://www.yfzcentral.com/forum/32-yfz- ... hread.html

http://www.thumperfaq.com/jetting.htm

LEAK JET for fcr's

http://www.yfzcentral.com/forum/32-yfz- ... hread.html

http://www.thumperfaq.com/jetting.htm

laughter is the best medicine

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Re: What did you do today? Cobba's rebuild

A little more thought into the oil temp sender and if I place the sensor in the oil tank as above, after running through the oil cooler, will this give me a true operating temperature as such???

I suppose it gives me a temperature that will be fed to the bottom end bearings.

Back into the garage and a quick clean up and inspection on the spare TRX motor sump/oil pan gave me a little more insight to things.

First option I looked at was and area plugged off and more than likely for an oil pressure switch.

This opens to the oil galley that feeds the crank itself right beside the 2nd or middle main bearing, but again the oil here is fed straight from the oil tank-pump-filter so has done no real work, but a good option to read if installing an oil pressure gauge.

(note this middle bearing does not feed the big end bearings on the conrods, no1 and no.3 take care of this)

The 2nd photo you can see the 3 outlets that feed the 3 main crank bearings and in turn via the galley inside the crank itself to the 2 big end bearings.

An other spot I looked at was by the oil filter but again, oil if fed from the oil tank through the pump ,then filtered before entering the rest of the motor.

Using the bottom drain plug or drilling and fitting directly to the bottom oil pan on the motor itself where the oil is picked up and pumped after doing it's duty throughout the motor will read the temperature once the oil has passed through the motor and before being pumped through the oil cooler.

After a little more deliberation, I'm thinking reading 3 litres of oil in the oil tank will give me more of a overall oil temperature reading plus the temperature of the oil the crank bearings will be fed, than 300-500ml in the bottom oil pan, or an oil galley with only a small amount of oil passing by it with a lot of influence from heat absorbed by the motor casings themselves.

I suppose it gives me a temperature that will be fed to the bottom end bearings.

Back into the garage and a quick clean up and inspection on the spare TRX motor sump/oil pan gave me a little more insight to things.

First option I looked at was and area plugged off and more than likely for an oil pressure switch.

This opens to the oil galley that feeds the crank itself right beside the 2nd or middle main bearing, but again the oil here is fed straight from the oil tank-pump-filter so has done no real work, but a good option to read if installing an oil pressure gauge.

(note this middle bearing does not feed the big end bearings on the conrods, no1 and no.3 take care of this)

The 2nd photo you can see the 3 outlets that feed the 3 main crank bearings and in turn via the galley inside the crank itself to the 2 big end bearings.

An other spot I looked at was by the oil filter but again, oil if fed from the oil tank through the pump ,then filtered before entering the rest of the motor.

Using the bottom drain plug or drilling and fitting directly to the bottom oil pan on the motor itself where the oil is picked up and pumped after doing it's duty throughout the motor will read the temperature once the oil has passed through the motor and before being pumped through the oil cooler.

After a little more deliberation, I'm thinking reading 3 litres of oil in the oil tank will give me more of a overall oil temperature reading plus the temperature of the oil the crank bearings will be fed, than 300-500ml in the bottom oil pan, or an oil galley with only a small amount of oil passing by it with a lot of influence from heat absorbed by the motor casings themselves.

laughter is the best medicine

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Re: What did you do today? Cobba's rebuild

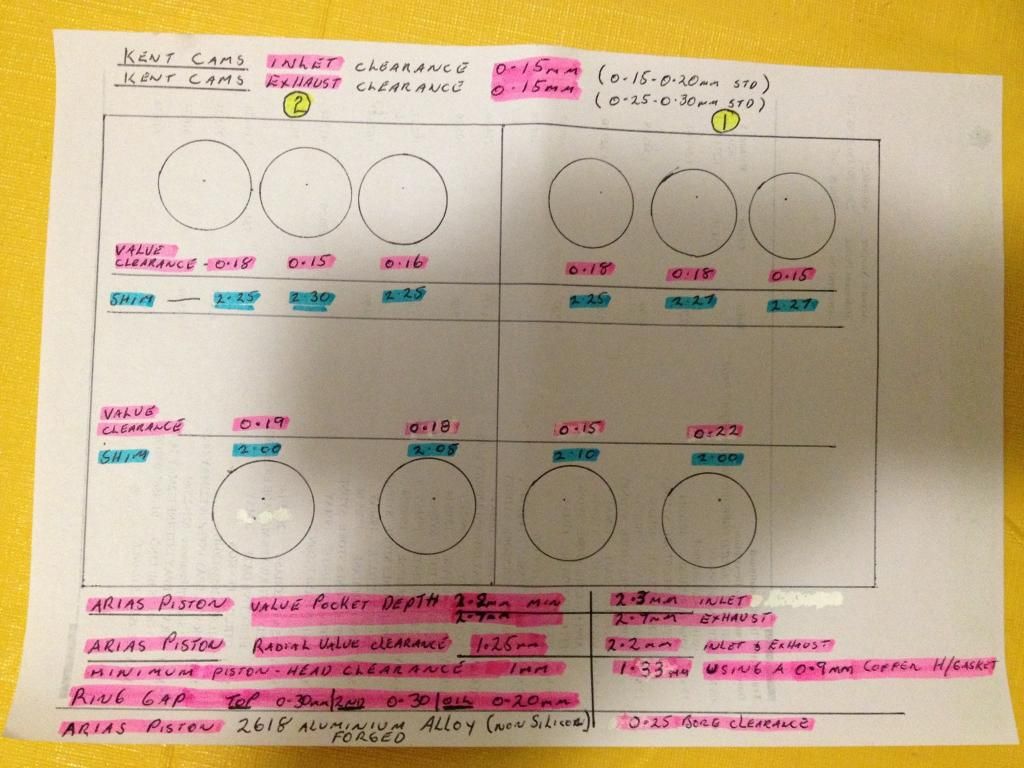

One final check before I continue splitting the cases once more so I may remove the crank to rebalance for the Arias pistons.

Out with the play doh again and while I had the head off I rechecked the valve clearances and jotted them down.

Then off with each bucket and check the shim size to make life easier when it comes to doing the valve clearances once again.

So I have all the info I need on one handy piece of paper.

All my valve clearance info, piston/valve clearances and assorted other important notes on ring gap and piston/head (squish clearance)

When I place a 2mm oversize valve into the valve pockets I can still see an easy 1mm+ clearance and if ever I go ahead using the 2mm oversize valves, I'm confident there will be enough clearance.

With the piston/valve clearances, I've allowed a little headroom and factored in to account for piston movement and using the play doh.

I feel confident even if any cam may be out a couple of degrees,I'll still have the clearance with the final dry run when going back together and cams timed.

Contact with Arias has confirmed minimum 1.5mm piston/valve clearance on both exhaust and inlet due to rod choice and valves/cams .

Higher tolerance was taken from JE piston site.

1.5mm P/V clearance is quite common clearance std on r1 models

Last edited by cobbadiggabuddyblooo on Fri Jan 23, 2015 2:51 pm, edited 2 times in total.

laughter is the best medicine

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Re: What did you do today? Cobba's rebuild

I have decided to go with placing the oil temperature sender in the back of the sump, just above where the outlet from the sump to the pump. There is extra material here to accommodate for the fixing screws on the oil pipe so enough material to run a thread for the sender. You can see by the first photo there is plenty of clearance with the tank and fuel tap.

The extra material on the sump wall allows for the complete thread to hold the sender and can easily be removed with no issues of using a threaded nut inside the sump to hold it inplace.

Inside the sump around this area there is plenty of extra material used as bracing and supports and this will act as a good heat sink and plenty of depth in the sump to give a good indication of the oil temperature.

laughter is the best medicine

- dicky

- Site Sponsor / Administrator

- Posts: 1106

- Joined: Thu Jan 06, 2005 11:26 am

- Location: Ruffy, Victoria.

Re: What did you do today? Cobba's rebuild

How full is the sump when the engine is running?

Will the sensor actually be covered, or just sitting in air?

Of all of the other places you were looking at but discarding because of temperature differences, how much is the actual difference, or are you just assuming that it will be a lot?

How much is a lot?

Do you actually care if the oil temp is 5 or 10 deg different from indicated?

I bet the water temp is not accurate, but we all know where the needle should be pointing to and we take note if it moves.

Oil temp would be the same. We know where it points to normally, and if it moves then something has changed.

If you are really super concerned about the actual oil temp then you'd better be putting multiple sensors in so that you can fully understand what is happening and where.

I reckon you are over-thinking this, but I still give you credit for at least doing it.

Will the sensor actually be covered, or just sitting in air?

Of all of the other places you were looking at but discarding because of temperature differences, how much is the actual difference, or are you just assuming that it will be a lot?

How much is a lot?

Do you actually care if the oil temp is 5 or 10 deg different from indicated?

I bet the water temp is not accurate, but we all know where the needle should be pointing to and we take note if it moves.

Oil temp would be the same. We know where it points to normally, and if it moves then something has changed.

If you are really super concerned about the actual oil temp then you'd better be putting multiple sensors in so that you can fully understand what is happening and where.

I reckon you are over-thinking this, but I still give you credit for at least doing it.

dicky

OOOSDC #5

OOOSDC #5

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Re: What did you do today? Cobba's rebuild

All a part of the learning curve Dicky.. If i don't make notes, with my memory it may be like ground hog day..

As I mentioned, I have the sender so I may as well put it to use.

If as you said, the water and oil temp are the same, maybe I should look into just using a bigger radiator, filling it full of oil and kill 2 birds

Thanks for the insight Dicky, I'll look at this option now.. That way I can ditch the sump all together

But what will that do to the centre of gravity, geometry and my damping setting... OOOOHHH I plenty here to keep me busy with all that weight hanging over the front end. Maybe use light weight oil????

"ll talk to the meerkats and compare the meerkat.com .au

Simple

All jokes aside,

Oil actually heats up faster than water and is holds it's heat longer than water as I have a feeling it doesn't conduct the heat out as easy as water from what I've read on the subject.

This is something else for me to learn about.

Every thing has an optimum working range so why not go there if I can find it..

Maybe the oil cooler will be too much for the bike and I don't meet that target.

I'll be able to find out this way.

Not much left standard on the motor now apart from the engine number.

If I get the chance to run this sump on the std motor in the bike at present, even better then it gives me a std reference point..

It's also one of the reasons I've been researching to find a thermo fan switch with a lower value.

The water will still heat up just as fast so it won't run cooler,but it will be managed better to keep within a certain threshold.

As I mentioned, I have the sender so I may as well put it to use.

If as you said, the water and oil temp are the same, maybe I should look into just using a bigger radiator, filling it full of oil and kill 2 birds

Thanks for the insight Dicky, I'll look at this option now.. That way I can ditch the sump all together

But what will that do to the centre of gravity, geometry and my damping setting... OOOOHHH I plenty here to keep me busy with all that weight hanging over the front end. Maybe use light weight oil????

"ll talk to the meerkats and compare the meerkat.com .au

Simple

All jokes aside,

Oil actually heats up faster than water and is holds it's heat longer than water as I have a feeling it doesn't conduct the heat out as easy as water from what I've read on the subject.

This is something else for me to learn about.

Every thing has an optimum working range so why not go there if I can find it..

Maybe the oil cooler will be too much for the bike and I don't meet that target.

I'll be able to find out this way.

Not much left standard on the motor now apart from the engine number.

If I get the chance to run this sump on the std motor in the bike at present, even better then it gives me a std reference point..

It's also one of the reasons I've been researching to find a thermo fan switch with a lower value.

The water will still heat up just as fast so it won't run cooler,but it will be managed better to keep within a certain threshold.

laughter is the best medicine

-

alextrx850

- Site Sponsor

- Posts: 2149

- Joined: Sat Apr 02, 2011 10:36 pm

- Location: brisbane AUSTRALIA

Re: What did you do today? Cobba's rebuild

the weight of the cooler with the plumbing alone would be going away from your weight saving direction.

Add the three or so hundred Mls of extra oil and all up there would be maybe half a kilo total added..

If a cooler was to be added, maybe put it in the return line back up to the top tank..

Also , when I replaced my cam chain a while ago, I was concerned to the two nylon oil pump drive gears and their purchase on their shafts...

Chances these could circulate at high rpm .

Add the three or so hundred Mls of extra oil and all up there would be maybe half a kilo total added..

If a cooler was to be added, maybe put it in the return line back up to the top tank..

Also , when I replaced my cam chain a while ago, I was concerned to the two nylon oil pump drive gears and their purchase on their shafts...

Chances these could circulate at high rpm .

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Re: What did you do today? Cobba's rebuild

That is where the oil temp sender is going in the sump Alex, not the cooler feed..

If I can keep constant HP by not loosing power due to heat , 1/2 kg is worth the sacrifice.

Especially with the temperatures of our summers..

If I can keep constant HP by not loosing power due to heat , 1/2 kg is worth the sacrifice.

Especially with the temperatures of our summers..

laughter is the best medicine

- dicky

- Site Sponsor / Administrator

- Posts: 1106

- Joined: Thu Jan 06, 2005 11:26 am

- Location: Ruffy, Victoria.

Re: What did you do today? Cobba's rebuild

Cobba,

I did not mean that the water and oil temps are the same. (but they will probably be very close)

What I meant was that what is shown on the water temp gauge may not be the actual water temp.

This has not been a concern to anyone that I know.

If you had an oil temp gauge, would it mater if the displayed temp was different to the actual temp?

As long as the displayed temp tracks the actual temp who cares what it is?

We all figure out the 'normal' running temp is and only care if it moves away from that.

I can't see any problem in measuring the oil temp at any of the places you have proposed, unless you fit an external oil cooler and measure directly after that.

Given your drive to reduce weight I can't see you fitting an external oil cooler.

It will gain you nothing.

Do you actually know how much power you lose for 1° temp change in the cylinder liner?

d

I did not mean that the water and oil temps are the same. (but they will probably be very close)

What I meant was that what is shown on the water temp gauge may not be the actual water temp.

This has not been a concern to anyone that I know.

If you had an oil temp gauge, would it mater if the displayed temp was different to the actual temp?

As long as the displayed temp tracks the actual temp who cares what it is?

We all figure out the 'normal' running temp is and only care if it moves away from that.

I can't see any problem in measuring the oil temp at any of the places you have proposed, unless you fit an external oil cooler and measure directly after that.

Given your drive to reduce weight I can't see you fitting an external oil cooler.

It will gain you nothing.

Do you actually know how much power you lose for 1° temp change in the cylinder liner?

d

dicky

OOOSDC #5

OOOSDC #5

- Rod.s

- Site Sponsor

- Posts: 1404

- Joined: Sun Apr 25, 2010 11:01 am

- Location: Brisbane, Australia

Re: What did you do today? Cobba's rebuild

All to true Dicky, the temp indicated is just a reference point, pure and simple. We will notice any fluctuations and respond accordingly. Place the oil temp sender where it is easiest. Once running stick a kitchen temp probe in the oil through the oil fill point and measure the difference. as the Meerkats would say, simples.dicky wrote:How full is the sump when the engine is running?

Will the sensor actually be covered, or just sitting in air?

Of all of the other places you were looking at but discarding because of temperature differences, how much is the actual difference, or are you just assuming that it will be a lot?

How much is a lot?

Do you actually care if the oil temp is 5 or 10 deg different from indicated?

I bet the water temp is not accurate, but we all know where the needle should be pointing to and we take note if it moves.

Oil temp would be the same. We know where it points to normally, and if it moves then something has changed.

If you are really super concerned about the actual oil temp then you'd better be putting multiple sensors in so that you can fully understand what is happening and where.

I reckon you are over-thinking this, but I still give you credit for at least doing it.

If it's not made in China, it's a fake!

-

Trixed

- TRX-Enthusiast

- Posts: 341

- Joined: Sat Jan 26, 2013 4:07 am

- Location: Brisbane Aus

Re: What did you do today? Cobba's rebuild

An air cooled engine would benefit a fair bit from an oil cooler as the oil takes the heat dissipation role to a greater extent (ie Ducati air cooled engines) than that of a liquid cooled engine. The TRX is a pretty cool running engine as is. Cooler oil is always better. However the question is whether it is necessary in a trx?

Cobba ultimately if u want one then just do it. Not many around with a cooler. Makes it more unique.

Cobba ultimately if u want one then just do it. Not many around with a cooler. Makes it more unique.

Last edited by Trixed on Sun Jan 18, 2015 1:35 pm, edited 1 time in total.

It is time to rev your hearts!

- Rod.s

- Site Sponsor

- Posts: 1404

- Joined: Sun Apr 25, 2010 11:01 am

- Location: Brisbane, Australia

Re: What did you do today? Cobba's rebuild

The cylinder temp is an important consideration, as the air fuel chemistry changes with temp, to cold-slow, incomplete and uneven, to hot-quick, incomplete and hot. So the consideration here is keeping the underside of the piston crown cool by using oil. Drop the temp of the oil you will also improve the combustion process, but all this is academic as the rods Cobba is using, unlike the factory rods, don't have this feature of force injected cooling oil into the underside of the piston crown.dicky wrote:Cobba,

I did not mean that the water and oil temps are the same. (but they will probably be very close)

What I meant was that what is shown on the water temp gauge may not be the actual water temp.

This has not been a concern to anyone that I know.

If you had an oil temp gauge, would it mater if the displayed temp was different to the actual temp?

As long as the displayed temp tracks the actual temp who cares what it is?

We all figure out the 'normal' running temp is and only care if it moves away from that.

I can't see any problem in measuring the oil temp at any of the places you have proposed, unless you fit an external oil cooler and measure directly after that.

Given your drive to reduce weight I can't see you fitting an external oil cooler.

It will gain you nothing.

Do you actually know how much power you lose for 1° temp change in the cylinder liner?

d

So keeping the chamber temp down is now up to the air/fuel inbound OR Coating the piston crown in ceramic material, this keeps the heat in the chamber to be exhausted out the valves eyc, not a bad thing as this reduces the surface contact temp of the piston and the radiant heat from the piston crown to the cylinder walls and ultimately the water jacket for cooling.

So Cobba, the point is that the oil in your engine is no longer doing one of it's most important jobs, cooling the piston crown; as you have coated the combustion chamber with a heat reflective ceramic coating; and the piston skirt with a friction reducing coating (friction = heat) the overall oil temp will be lower. So the oil temp you measure will, as i said "be academic"

Last edited by Rod.s on Sun Jan 18, 2015 1:10 pm, edited 1 time in total.

If it's not made in China, it's a fake!