I read around that many people use JE 878cc kits. Which is a 1.5mm oversize piston. After ringing my local JE supplier (well, ~2200km away, in QLD) i found out that they were "locked" to a supplier somewhere in Europe. And couldnt find out who it exactly was. I had 2 choices.. Find that supplier, hopefully he doesnt make me bleed like a cut pig for them, or get some new custom ones made.

TDM900 i thought.. yer.. they are the same block as TRX, but re-sleeved. So i knew it was very possible to do.

I punched out my old sleeves, got some new ones made. I didnt want nikosil coating, as thats fairly much dependant on the piston / rings you are using. Todays tech doesnt really require it.. Sure its good if you have it, but its not really needed if you use the correct parts all together. Saying that, many factory vehicles still use nikosil, which cant be a bad thing.

3 pistons.. 2 wrist / gudgeon pins. TRX850 on the left, TDM900 in the middle, new 907cc on the right.

TRX is 89mm, JE 878cc kits are 90.5mm, TDM are 91mm, the 907cc are 91.5mm (+2.5mm)

Compression is 10.4:1 - 10.5:1 depending on where you look. The 907cc is 12.5:1

The wrist pin on the left is TRX stock, the right is the new one from JE. I dont have a TDM one for reference, but its same size as the TRX, but its 1mm bigger diameter.

Top view.. You can clearly see the dishing on the TRX and TDM units.

Also note the taper on the TRX gudgeon pin, while the JE doesnt have one. They appear to be the same internal diameter, altho i havnt measured it to confirm

You can clearly see the raised portion of the JE piston. This was measured in accordance with a mold impression of the head that had to be made. If a TRX piston is flat rather than dished, it puts compression to 11.2:1. Which is fine, but since i control spark and am almost complete on the EFI side of things, i know i can run higher compression safely.

The TRX piston. Not the best of shots. But you can see the casting radius and surface quality in this shot. This piston is re-usable. No cracks and only requires cleaning to look like new again. Came off a ~60,000km bike in australia.

Underside. TRX has no land build up at all. Skirt is the widest of the lot, has 5 oiling holes all comming from the inside of the piston. The 4 holes that are above the gudgeon pin hole, go thru to the sides of the pin. I suspect they are for oiling purposes. But thats a guess.

TDM has a little landing support. Side skirt is narrower and has 3 oil holes on the inside, and one on each side of it. The 2 shiny lumps are casting spiggots that have been machined off. They could be machined more and radius'd and cleaned up for additional weight saving if required. The TDM piston is obviously a touch heavier than a TRX. I have not weighed the pistons as yet, but its very obvious.

JE piston has quite a pronounced landing, and the narrowest skirt of the lot. 3 oil holes on the inside, and 2 comming out from a hole drilled thru the 2 raised bits on the landing, at the end of the gudgeon pin hole. You can just see one of the drill holes on the right side of the JE piston, inside the pin hole. The JE also has extensive machining on the bottom. Its actually a "wave" not a pure curved surface. Starts high, drops down, raises up over the pin hole, back down, up high to the other side of the skirt.

Piston heights.. Fairly obvious. TRX the tallest.. Not sure if this has some relevance to diameter. Bigger it is, flatter it gets. You can also see the 5 oil holes in the TRX / TDM pistons in the lower ring hole. You can also make out the 3 in the JE, and one on the left hand side of it.

One thing ill also note, if you pay attention to the top of the piston, to the first ring. Notice that the JE has the thinnest top ? This is to do with emission control. If its too thin it cracks and weakens the piston, but if its too thick, excess oil / carbon stores up and can hurt you on the emission test. This is what ive been told. Ive obviously not tested it as yet. Time will tell.

Also the skirts taper back into the pin area. While the JE is relatively flat in comparison.

Mold impression. Made with fibreglass resin and a thin layer of oil. Assemble the block to the head.. Hold with clamps of some sort, spray a quick squirt of WD40 in, or wipe with some oil on a rag. Make sure you dont have any excess oil pooled up in any corner. Pour in some resin. Wait a few mins, repeat until you have ~15mm (just shy of 3/4" for the mexicans reading this) up the side wall. Let it set for a solid 24hrs as its quite thick. gently twist the head off the cylinder block. gently pry the mold out of the head.. Takes a bit of wrestling, but its possible with a touch of patience.

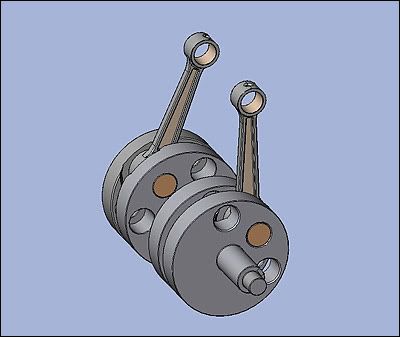

Well, thats about all for now. Ive got to get the whole lot balanced again. The JE piston is LIGHTER than the TRX unit. Its quite noticable. Ill get a scale and get it all written up about exact weights. Matched with some new Carrillo conrods i already have, it should be fairly solid for most anything i throw at it now.

Oh. The JE piston has 1mm oversize pockets to accecpt oversize valves if required. Which is a nice benefit since 907cc does require a bit more air. So at a future date, ill get that sorted.

Enjoy.