What's next?

Moderators: trixynut, Mincehead, dicky, phuk72, Jak, Kevtrx849

- SDN

- Site Sponsor

- Posts: 760

- Joined: Sat Jan 23, 2010 2:26 pm

- Location: Birmingham

What's next?

I have bought a R1 5PW set of frontg yokes which I will fit to take the offset back to standard TRX spec 98 - 00 have a bigger off set, I want to quicken up the steering

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Re: What's next?

One thing I noticed about the longer 98-99 (135mm travel) R1 forks is the damping and turn in between a full and empty tank.

I can feel the damping stiffening up by the time I'm down to the last 6 litres and it understeers a little out of corners . It's like my wake up call that I'm goin to need fuel soon.

As the lads found out yesterday on our ride . Made it with 1/2 litre left inside the tank to the servo at Esk.

I can feel the damping stiffening up by the time I'm down to the last 6 litres and it understeers a little out of corners . It's like my wake up call that I'm goin to need fuel soon.

As the lads found out yesterday on our ride . Made it with 1/2 litre left inside the tank to the servo at Esk.

laughter is the best medicine

- SDN

- Site Sponsor

- Posts: 760

- Joined: Sat Jan 23, 2010 2:26 pm

- Location: Birmingham

Re: What's next?

I generally keep an eye on the trip gauge refuel at 120 miles and reset after refuelling, I have yet to master being able to get fuel onto reserve on the move, I usually pull over as it starts to splutter cos fiiddling about under the tank in traffic has never seemed the safest option to me

-

Trixed

- TRX-Enthusiast

- Posts: 341

- Joined: Sat Jan 26, 2013 4:07 am

- Location: Brisbane Aus

Re: What's next?

LikewiseSDN wrote:I generally keep an eye on the trip gauge refuel at 120 miles and reset after refuelling, I have yet to master being able to get fuel onto reserve on the move, I usually pull over as it starts to splutter cos fiiddling about under the tank in traffic has never seemed the safest option to me

It is time to rev your hearts!

-

alextrx850

- Site Sponsor

- Posts: 2149

- Joined: Sat Apr 02, 2011 10:36 pm

- Location: brisbane AUSTRALIA

Re: What's next?

Generally find the fuel tap easy to access....

If the tap knob has a flat spot ..its on open tank.

If I have a pointy end to the top.....its on reserve..

If the tap knob has a flat spot ..its on open tank.

If I have a pointy end to the top.....its on reserve..

-

dfh

- TRX-Enthusiast

- Posts: 287

- Joined: Sat Nov 04, 2006 1:39 am

- Location: Adelaide South Australia.

Re: What's next?

Sounds more like a tad too much front preload to me.....cobbadiggabuddyblooo wrote:One thing I noticed about the longer 98-99 (135mm travel) R1 forks is the damping and turn in between a full and empty tank.

I can feel the damping stiffening up by the time I'm down to the last 6 litres and it understeers a little out of corners .

Now with 140,000 on the clocks, X-mas tree didn't kill it & I still love it.

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Re: What's next?

Sag is set front and rear with a full tank and its only once down to the last few litres that it starts to under steer just a little. Most times I'll refuel when down to 1/3-1/4 tank so not really an issue.

Damping and rebound are set for full to half tank too.

It's not till you get down to 1/3 tank that you dont get fuel spilling forward to the front of the tank too.

I still have 9mm from the cable tie till forks bottom out (135mm) when riding aggressively so I'm not using all the travel but i have that little more incase of pot hole or large bump that just suddenly appears.

All in all I'm happy though with the set up.

Std trx front travel is 120mm

Damping and rebound are set for full to half tank too.

It's not till you get down to 1/3 tank that you dont get fuel spilling forward to the front of the tank too.

I still have 9mm from the cable tie till forks bottom out (135mm) when riding aggressively so I'm not using all the travel but i have that little more incase of pot hole or large bump that just suddenly appears.

All in all I'm happy though with the set up.

Std trx front travel is 120mm

laughter is the best medicine

- SDN

- Site Sponsor

- Posts: 760

- Joined: Sat Jan 23, 2010 2:26 pm

- Location: Birmingham

Re: What's next?

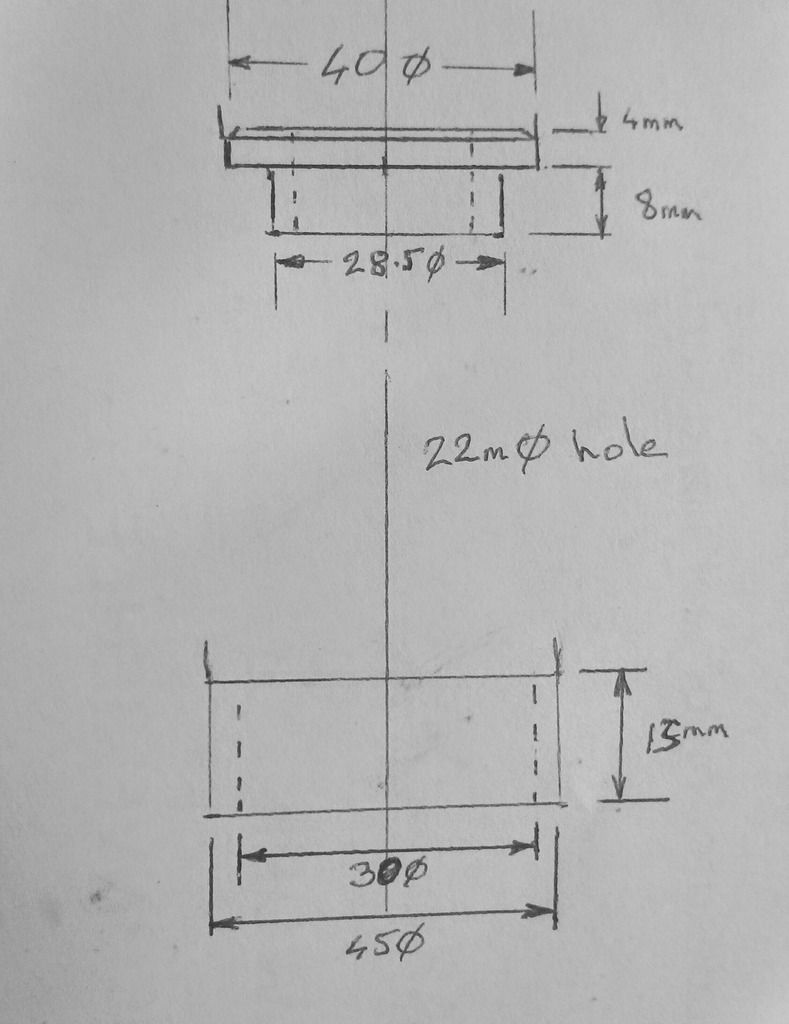

Info required as am machining up the fork stem for a press fit through new bottom yoke this afternoon, when everyone has pissed of home and I cann use the lathe! I also want to restore frok length to standard so I want to machine a spacer and fit it on the stem between the bottom yoke and the bearing. What I need to know fairly urgently, is how far above the top yoke do the handlebars on standard forks go? I know all the other dimensions and can work out the spacer. But I need this infor today, before 16:00 GMT! I will also but it out on tech queries

- SDN

- Site Sponsor

- Posts: 760

- Joined: Sat Jan 23, 2010 2:26 pm

- Location: Birmingham

Re: What's next?

Ready to start big piece of billet ali

Even did a drawing!

To bring the R1 forks to standard TRX length I cut the steering stem and tapped each side 3/8 BSP in a lathe to ensure was true, Turned two shoulders on a piece of 1" steel bar and ran 3/8 BSP threads on them, then screwed the spacer into each side of the steering stem. Then clocked it up in the lathe to ensure concentricity. Note chamfers either side of the joins to allow me to get a good weld.

Just have to weld it together - will tack it in the vice to keep straight before bollocking weld round stem joins ans will clock it all in the vice to ensure it runs true - probably require some percussion adjustment LOL

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Re: What's next?

What about if you just used another bottom yoke, put in a sleeve for the narrower stem diameter, machine off the 2 steering lock stoppers and to allow for clip on fittment remove some off the bottom of the fork mounts.

There is your stepped top yoke and just fit the std stem.

You may be able to machine the top of the fork mount and place the bars ontop.

There is your stepped top yoke and just fit the std stem.

You may be able to machine the top of the fork mount and place the bars ontop.

laughter is the best medicine

- SDN

- Site Sponsor

- Posts: 760

- Joined: Sat Jan 23, 2010 2:26 pm

- Location: Birmingham

Re: What's next?

Many way to do the same thing cobba this just seemed Cheap and easily within my skill set and what I had available to me in terms of machinery and materials - did I mention low cost - LOL

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Re: What's next?

Lucky man, I unfortunately need to take mine to an engineering shop for such mods.

laughter is the best medicine

- SDN

- Site Sponsor

- Posts: 760

- Joined: Sat Jan 23, 2010 2:26 pm

- Location: Birmingham

Re: What's next?

Yeah I know -

unfortunately work is selling off the workshop lathe as they don't have anyone who can use it (apart from me and I'm the bloody manager) So I'll have to get this all done and look for someone / where else to borrow a lathe off -

Funnily enough Worcester Hospital (where I work) has a new radiotherapy department, with a medical physics engineering work shop and guess what? A lathe and a milling m/c ho ho - looks like I'm back in business

Just have to make sure I get all their repairs and maintenance done

unfortunately work is selling off the workshop lathe as they don't have anyone who can use it (apart from me and I'm the bloody manager) So I'll have to get this all done and look for someone / where else to borrow a lathe off -

Funnily enough Worcester Hospital (where I work) has a new radiotherapy department, with a medical physics engineering work shop and guess what? A lathe and a milling m/c ho ho - looks like I'm back in business

Just have to make sure I get all their repairs and maintenance done

-

Rich

- Site Sponsor

- Posts: 217

- Joined: Mon Dec 23, 2013 8:20 pm

- Location: Derbyshire UK

Re: What's next?

I held mine in V blocks for tacking / welding clamped up to a flat plate rather than clamped in the vice. Gave good results in the accuracy stakes

- SDN

- Site Sponsor

- Posts: 760

- Joined: Sat Jan 23, 2010 2:26 pm

- Location: Birmingham

Re: What's next?

Oh did you extend your steering stem?

Yes I do agree that using V Blocks would be better, but I dont have a surface plate and my V Blocks which I made as an apprentice, dont have clamps - so I have made do with what I had.

Did all the welding Saturday and I will put the shaft in the lathe and clock both ends with a DTI for accuracy before machining off the excess weld

Hopefully can then build the front end back up.

Oh yes, just bought an R6 radiator as I fitted a lower temperature fan switch and the fan seemed to be coming on an awful lot it traffic, so bigger rad seemed a good idea espcially as weather id gettinng warmer.

I was considering using some aluminium brazinng rods on blanking plugsand to attache fixing lugs to the side - anyone tried these?

Yes I do agree that using V Blocks would be better, but I dont have a surface plate and my V Blocks which I made as an apprentice, dont have clamps - so I have made do with what I had.

Did all the welding Saturday and I will put the shaft in the lathe and clock both ends with a DTI for accuracy before machining off the excess weld

Hopefully can then build the front end back up.

Oh yes, just bought an R6 radiator as I fitted a lower temperature fan switch and the fan seemed to be coming on an awful lot it traffic, so bigger rad seemed a good idea espcially as weather id gettinng warmer.

I was considering using some aluminium brazinng rods on blanking plugsand to attache fixing lugs to the side - anyone tried these?