Please share your secrets! What mods have you made to your TRX?

Moderators: trixynut, Mincehead, dicky, phuk72, Jak, Kevtrx849

-

SDN

- Site Sponsor

- Posts: 760

- Joined: Sat Jan 23, 2010 2:26 pm

- Location: Birmingham

Post

by SDN » Sun Feb 01, 2015 9:50 am

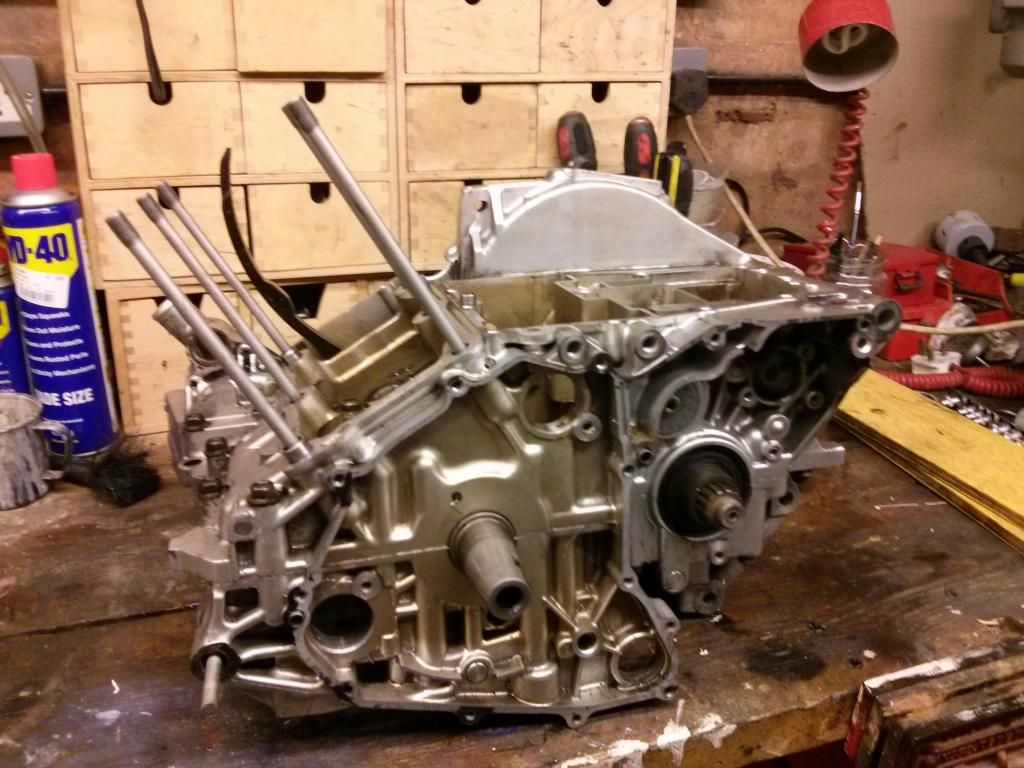

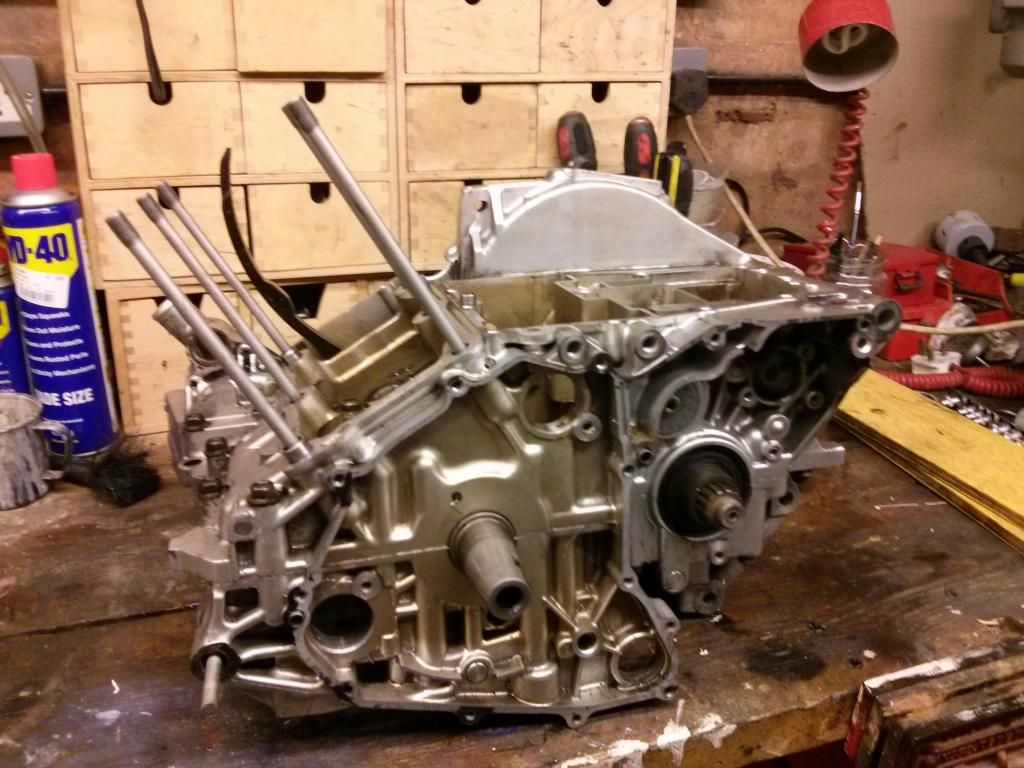

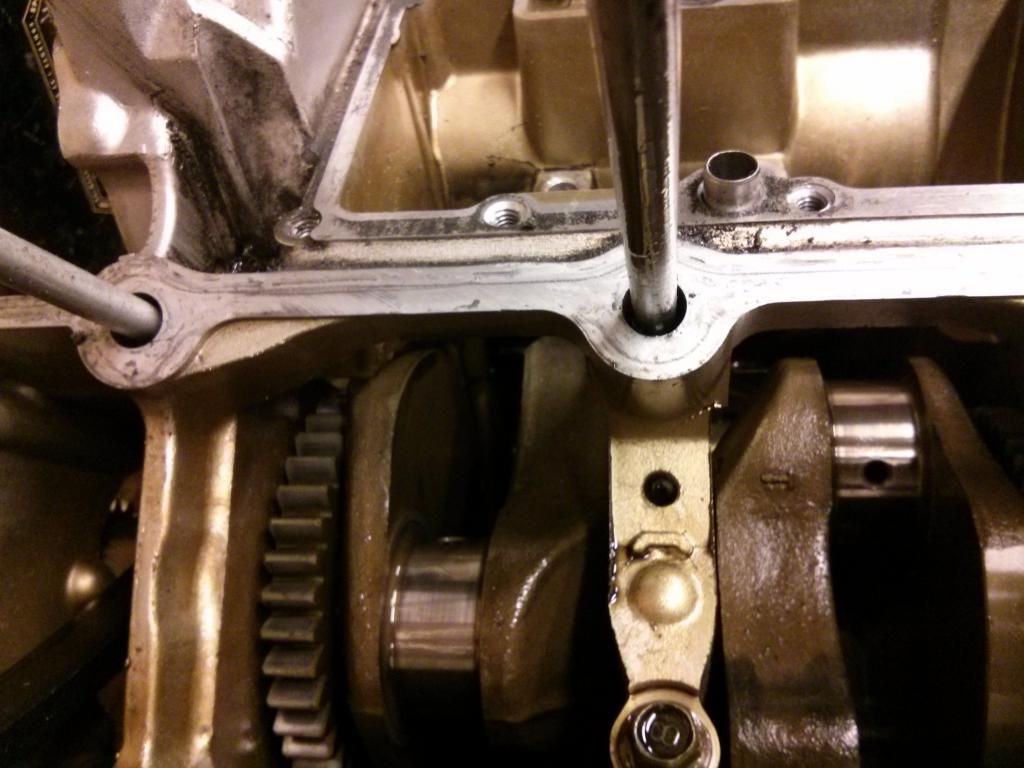

started as you can see

Just got to see if I remember how to upload photos - alternator was a b*stard to get off home mad puller and electric impact gun sorted it with a bang

-

SDN

- Site Sponsor

- Posts: 760

- Joined: Sat Jan 23, 2010 2:26 pm

- Location: Birmingham

Post

by SDN » Sun Feb 01, 2015 9:57 am

Got clutch off will now need to make clutch holding tool with a spare clutch plate, bit of metal bar and my trust clarke welder - thank god for machine mart

I will try to get the bottom crankcase off without removing head and barrells if possible - has anyone done this before?

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Post

by cobbadiggabuddyblooo » Sun Feb 01, 2015 12:15 pm

There is a crankcase bolt right under where the barrels live Simon so out of luck with that one mate.

Bolt no 21 of the crankcase securing bolts.. Page 4-53 on the service manual..

laughter is the best medicine

-

SDN

- Site Sponsor

- Posts: 760

- Joined: Sat Jan 23, 2010 2:26 pm

- Location: Birmingham

Post

by SDN » Sun Feb 01, 2015 12:40 pm

shit - cheers cobba, oh well onwards and upwards - have spare TDM gear cluster to drop in if necessary

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Post

by cobbadiggabuddyblooo » Sun Feb 01, 2015 3:10 pm

Just be aware of the ratios on the TDM 1st gear Simon . Great for climbing trees but 2nd to 5th are the same as the TRX

Transmission Type Constant mesh 5-speed

Gear Ratio 1st 37/13 (2.846)

Gear Ratio 2nd 37/20 (1.850)

Gear Ratio 3rd 30/21 (1.429)

Gear Ratio 4th 27/23 (1.174)

Gear Ratio 5th 28/27 (1.037)

Transmission TRX850:

Clutch type = Coil spring Wet multiple disc

Transmission type = Constant mesh 5-speed

Gear ratios = 1st: 2.571,

2nd: 1.850, 3rd: 1.428, 4th: 1.173, 5th: 1.037

laughter is the best medicine

-

SDN

- Site Sponsor

- Posts: 760

- Joined: Sat Jan 23, 2010 2:26 pm

- Location: Birmingham

Post

by SDN » Sun Feb 01, 2015 11:38 pm

Some progress today, clutch out, and pretty much ready to split cases. A bit of a bummer seeing some, not a lot of pick up on small ends - hopefully big ends / mains are OK.On the gearbox front, could just swap faulty 3rd gear components + got selector forks and drum, hopefully make 1 good gearbox from the two - fingers crossed

-

SDN

- Site Sponsor

- Posts: 760

- Joined: Sat Jan 23, 2010 2:26 pm

- Location: Birmingham

Post

by SDN » Mon Feb 02, 2015 8:35 pm

Latest pics - don't reckon I'll get much more done until weekendhttp://rs938.pbsrc.com/albums/ad225/sdnoon/Mobile%20Uploads/image-4.jpg~320x480

Just trying tablet to upload PIC - see if it works!

-

SDN

- Site Sponsor

- Posts: 760

- Joined: Sat Jan 23, 2010 2:26 pm

- Location: Birmingham

Post

by SDN » Mon Feb 02, 2015 8:40 pm

-

SDN

- Site Sponsor

- Posts: 760

- Joined: Sat Jan 23, 2010 2:26 pm

- Location: Birmingham

Post

by SDN » Mon Feb 02, 2015 8:41 pm

Last try

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Post

by cobbadiggabuddyblooo » Tue Feb 03, 2015 5:29 am

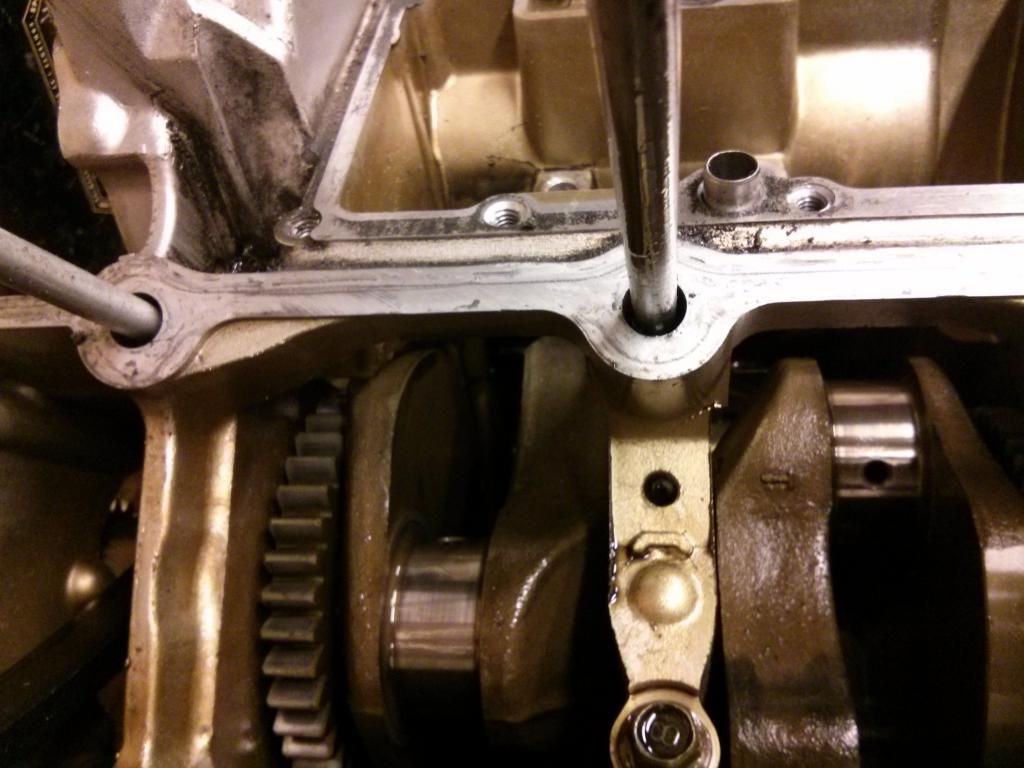

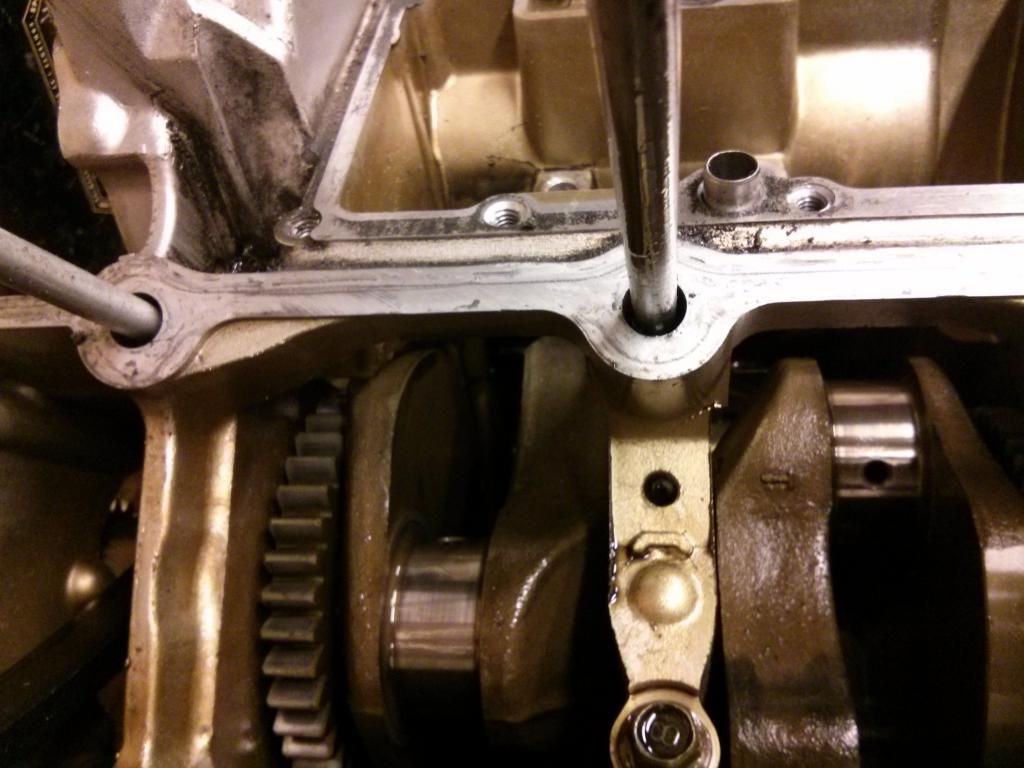

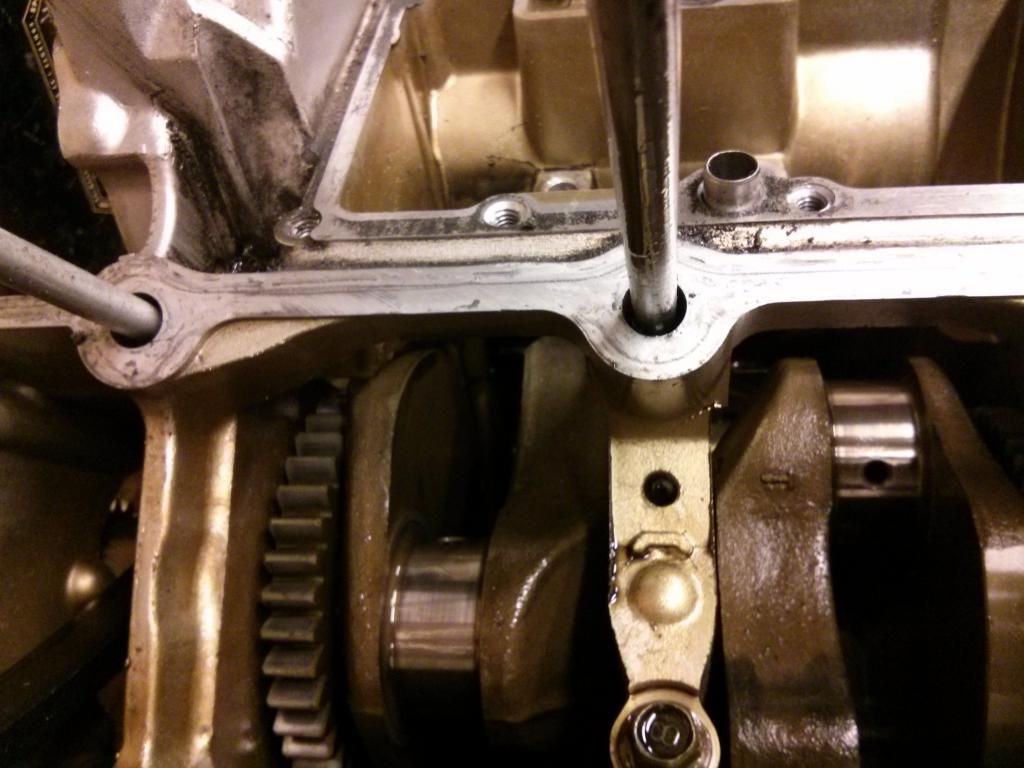

Not far to go Simon, all pretty well just unbolted from here.

Only dicky thing is the 3 screws holding in the gearbox shaft that are punched which isn't too much of an issue.

Balance shafts just slip out once the retaining screw is removed from the plate and easily slip back in.

The workshop manual has all the details on aligning them both with the crank and its pretty straight forward.

Be interested to see what crud the screens have picked up in the top and bottom sumps.

Top sump on mine was restricted with half of the screen clogged with guff and the bottom return screen had found a stringy bit of silicone from a previous rebuild in its life.

Bores seem pretty hardy on the trx , how did the fair??

laughter is the best medicine

-

SDN

- Site Sponsor

- Posts: 760

- Joined: Sat Jan 23, 2010 2:26 pm

- Location: Birmingham

Post

by SDN » Tue Feb 03, 2015 10:10 am

Bores were good, cleaned them up when I fiited kent cams and fitted new rings. I also had the head ported, with new valve seals fitted, which stopped the comical (not) oil consumption.

Small ends have some witnesss marks on gudgeon pin but no deep scores and can feel no appreciable play - so I reckon I will stick them back in - unless there is a cheap cheerful fix, like bushing the co rod?

Fingers crossed for mains and big ends - hopefully no wear or scoring.

-

SDN

- Site Sponsor

- Posts: 760

- Joined: Sat Jan 23, 2010 2:26 pm

- Location: Birmingham

Post

by SDN » Sat Feb 07, 2015 7:39 pm

-

SDN

- Site Sponsor

- Posts: 760

- Joined: Sat Jan 23, 2010 2:26 pm

- Location: Birmingham

Post

by SDN » Sat Feb 07, 2015 7:47 pm

Well nearly ready to split cases the balance weight bolts were a bastard, had to drill them out, the big bearings ends are good and shells have very little wear

Bought a parts washer from machine mart to clean everything up as there is quite a lot of sludgy deposits

Finger crossed will find the probem with 3rd gear, then can start building it back up

Got some silver engine paint - hycote aluminium - tin says it is petrol resistant, but Chris had some issues with it and had to lacquer it - any further info on that?

Last edited by

SDN on Sun Feb 08, 2015 8:38 am, edited 2 times in total.

-

SDN

- Site Sponsor

- Posts: 760

- Joined: Sat Jan 23, 2010 2:26 pm

- Location: Birmingham

Post

by SDN » Sat Feb 07, 2015 7:51 pm

I might even try dialling in the cam, as I do have a DTI just need to get a timing wheel. Also have some spare cam sprockets I can slot, must remember to set all valve clearances at 0.15 for the Kent cams

-

SDN

- Site Sponsor

- Posts: 760

- Joined: Sat Jan 23, 2010 2:26 pm

- Location: Birmingham

Post

by SDN » Tue Feb 10, 2015 10:01 am

Total strip down now achieved, down to bear cases and cleaning up accumulated crud off - may even try the diswaher one late night - if the wife ever finds out Iwill be toast!

Mains look good and shells.

Gearbox problem on 3rd seem to be merginal engagement due to accumulation of wear, will try TDM box, before I try splitting the cluster - it's easier to deal with assemblies, less time consuming!

What sealant do people use onn the crankcases?