12 - 14mm plug adaptor

Moderators: trixynut, Mincehead, dicky, phuk72, Jak, Kevtrx849

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

12 - 14mm plug adaptor

Shopping around to see if I can find a 12-14mm plug adaptor to make up a piston stop to screw into the head to locate TDC.

Plenty of 14mm adaptors out there under $10 so anyone in OZ tracked these 12mm adaptors down??

Other option I thought may be to get a 12mm/1.25 pitch bolt long enough to do the job as the motor is out of the frame.

I'm sure they would be available to use on compression , leak down test kits too so may be listed as a spare.

Plenty of 14mm adaptors out there under $10 so anyone in OZ tracked these 12mm adaptors down??

Other option I thought may be to get a 12mm/1.25 pitch bolt long enough to do the job as the motor is out of the frame.

I'm sure they would be available to use on compression , leak down test kits too so may be listed as a spare.

laughter is the best medicine

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Re: 12 - 14mm plug adaptor

Found one in the US and its an adaptor for a compression tester.

It has a small hole where the spark plug tip usually would be so perfect and I'll tap a thread in there and screw in a button head cap screw for a nice soft edge on the piston..

It has a small hole where the spark plug tip usually would be so perfect and I'll tap a thread in there and screw in a button head cap screw for a nice soft edge on the piston..

laughter is the best medicine

-

Rich

- Site Sponsor

- Posts: 217

- Joined: Mon Dec 23, 2013 8:20 pm

- Location: Derbyshire UK

Re: 12 - 14mm plug adaptor

alternatively:

put a coach bolt through it with a nut on the outside, gives you a smooth domed surface.

rod acting on a dial guage.

put a coach bolt through it with a nut on the outside, gives you a smooth domed surface.

rod acting on a dial guage.

- QuickDraw

- Site Sponsor

- Posts: 165

- Joined: Thu Dec 16, 2010 9:06 am

- Location: Sunshine Coast, QLD

- Contact:

Re: 12 - 14mm plug adaptor

You can also just break & bore out an old TRX plug, then run a long bolt through that. Secured with a nut of course. If you use an extra long bolt or some threaded rod, you could make it long enough to screw in by hand without even bothering with the plug socket.

-

alextrx850

- Site Sponsor

- Posts: 2149

- Joined: Sat Apr 02, 2011 10:36 pm

- Location: brisbane AUSTRALIA

Re: 12 - 14mm plug adaptor

Winner !QuickDraw wrote:You can also just break & bore out an old TRX plug, then run a long bolt through that. Secured with a nut of course. If you use an extra long bolt or some threaded rod, you could make it long enough to screw in by hand without even bothering with the plug socket.

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Re: 12 - 14mm plug adaptor

Healthy ideas but I looked into modding a spark plug and came to a conclusion its a lot of work to restructure the spark plug for the task and ceramic is such a hard material.

That's why the search for an easier alternative.

Here all I need to do is the simple button head mod on the bottom end, then just lock a 14mm diameter bolt into the top end of the adaptor with enough length so a plug spanner is not needed.

( being a 12mm male to 14mm female adaptor)

This also allows me to remove the 14mm top bolt if access is an issue with the motor still in the frame or you choose to use a dial gauge with the button head bolt removed too and just use a plug spanner to locate it into the head.

Cost ($6) so under $15 with shipping from the US but I'm sure there would be some dist. locally who would sell these for a similar price..

Thanks for the input guys. It's always good to promote some healthy discussions on ideas.

That's why the search for an easier alternative.

Here all I need to do is the simple button head mod on the bottom end, then just lock a 14mm diameter bolt into the top end of the adaptor with enough length so a plug spanner is not needed.

( being a 12mm male to 14mm female adaptor)

This also allows me to remove the 14mm top bolt if access is an issue with the motor still in the frame or you choose to use a dial gauge with the button head bolt removed too and just use a plug spanner to locate it into the head.

Cost ($6) so under $15 with shipping from the US but I'm sure there would be some dist. locally who would sell these for a similar price..

Thanks for the input guys. It's always good to promote some healthy discussions on ideas.

laughter is the best medicine

- Rod.s

- Site Sponsor

- Posts: 1404

- Joined: Sun Apr 25, 2010 11:01 am

- Location: Brisbane, Australia

Re: 12 - 14mm plug adaptor

Why would you need to find TDC? As the TDC will never change, unless the crank has been striped and rebuilt? TDC is reliant on the crank being in alignment and there would have to be a catastrophic event to alter the crank alignment. Did the crank guy strip your crank?cobbadiggabuddyblooo wrote:Healthy ideas but I looked into modding a spark plug and came to a conclusion its a lot of work to restructure the spark plug for the task and ceramic is such a hard material.

That's why the search for an easier alternative.

Here all I need to do is the simple button head mod on the bottom end, then just lock a 14mm diameter bolt into the top end of the adaptor with enough length so a plug spanner is not needed.

( being a 12mm male to 14mm female adaptor)

This also allows me to remove the 14mm top bolt if access is an issue with the motor still in the frame or you choose to use a dial gauge with the button head bolt removed too and just use a plug spanner to locate it into the head.

Cost ($6) so under $15 with shipping from the US but I'm sure there would be some dist. locally who would sell these for a similar price..

Thanks for the input guys. It's always good to promote some healthy discussions on ideas.

If it's not made in China, it's a fake!

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Re: 12 - 14mm plug adaptor

Because I feel this is a more sensible way to locate TDC when calibrating the camshaft timing degree wheel.

http://www.ebay.com.au/itm/310878224920 ... 1439.l2649

I could place a solid bar across the pistons and calibrate the wheel that way but there is a chance the pointer I make up may be bumped when placing the head and cams into place.

So if all is bolted together and then start the process of dialling in the cams seems a lot less chance for error plus I can always reference TDC and check the timing wheel is correct at any time without dismantling if need be.

A fun week coming up doing dry runs with both sets of barrels and I'll have the opportunity to mark the valve relief's just to make sure the valves are central to them.

Danny is rebuilding his head at present so I'll use that while the valves are out.

It may seem like a long way around things but I'll have peace of mind that all should be where it is suppose to be and within the tolerances.

http://www.ebay.com.au/itm/310878224920 ... 1439.l2649

I could place a solid bar across the pistons and calibrate the wheel that way but there is a chance the pointer I make up may be bumped when placing the head and cams into place.

So if all is bolted together and then start the process of dialling in the cams seems a lot less chance for error plus I can always reference TDC and check the timing wheel is correct at any time without dismantling if need be.

A fun week coming up doing dry runs with both sets of barrels and I'll have the opportunity to mark the valve relief's just to make sure the valves are central to them.

Danny is rebuilding his head at present so I'll use that while the valves are out.

It may seem like a long way around things but I'll have peace of mind that all should be where it is suppose to be and within the tolerances.

laughter is the best medicine

- Rod.s

- Site Sponsor

- Posts: 1404

- Joined: Sun Apr 25, 2010 11:01 am

- Location: Brisbane, Australia

Re: 12 - 14mm plug adaptor

Fairs fair, You can also dial the cams without putting the head on the block. Quicker and easer on the bench, as you know the valve opening/closing Deg, use a dia gauge to measure the valve movement. If the deg before TDC is 38deg this = static valve opening of 1mm of valve movement (universal acceptance of valve opening is 1mm open), using the dia gauge this will give you the known deg/point (1mm of valve movement = 38Deg) then do the same for closing and you then have two correct points of reference, half that is TDC of cam, mark that and all's good. Assemble as normal with the slotted cam sprockets, bring engine to TDC compression, align cams to the TDC mark and then tighten sprocket bolts. Rotate engine one revolution clockwise then, double check with dial gauge and deg wheel…cobbadiggabuddyblooo wrote:Because I feel this is a more sensible way to locate TDC when calibrating the camshaft timing degree wheel.

http://www.ebay.com.au/itm/310878224920 ... 1439.l2649

I could place a solid bar across the pistons and calibrate the wheel that way but there is a chance the pointer I make up may be bumped when placing the head and cams into place.

So if all is bolted together and then start the process of dialling in the cams seems a lot less chance for error plus I can always reference TDC and check the timing wheel is correct at any time without dismantling if need be.

A fun week coming up doing dry runs with both sets of barrels and I'll have the opportunity to mark the valve relief's just to make sure the valves are central to them.

Danny is rebuilding his head at present so I'll use that while the valves are out.

It may seem like a long way around things but I'll have peace of mind that all should be where it is suppose to be and within the tolerances.

You can still have the left engine case attached (giving a correct and known TDC) and a Deg wheel attached to the shaft, best of both worlds, make a male/female adaptor around 40mm long and use that.

Using the touch method (solid pointer on piston crown) will only work if you are chasing an angle before or after TDC and you can lock the bolt/adaptor, it will not find true TDC as there is a significant amount of crank movement with little or no measurable piston movement, a measurable amount of thread slop in the bolt/adaptor. With this head design you wont be able to lock either the bolt or the adaptor so this route is not a sensible way to measure TDC when TDC is already marked and easily found.

Remembering that TDC is only a measurement of crank rotation.

An't this a fun learning experience

If it's not made in China, it's a fake!

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Re: 12 - 14mm plug adaptor

BOSS BOSS... THE CHAIN THE CHAIN

Doesn't this dictate when at TDC, where the cam sprocket sits in relation to the cams and why you need to dial in the cam timing using a slotted hole in the sprocket???

Surely I wouldn't have any slop with the adaptor screwed into the plug hole and with the plug central to the piston, piston rock would not come into play.

If the Yamaha TDC marks are spot on, then using the stop method would only confirm this as an absolute don't you think???

Doesn't this dictate when at TDC, where the cam sprocket sits in relation to the cams and why you need to dial in the cam timing using a slotted hole in the sprocket???

Surely I wouldn't have any slop with the adaptor screwed into the plug hole and with the plug central to the piston, piston rock would not come into play.

If the Yamaha TDC marks are spot on, then using the stop method would only confirm this as an absolute don't you think???

Last edited by cobbadiggabuddyblooo on Mon Dec 15, 2014 10:57 am, edited 1 time in total.

laughter is the best medicine

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Re: 12 - 14mm plug adaptor

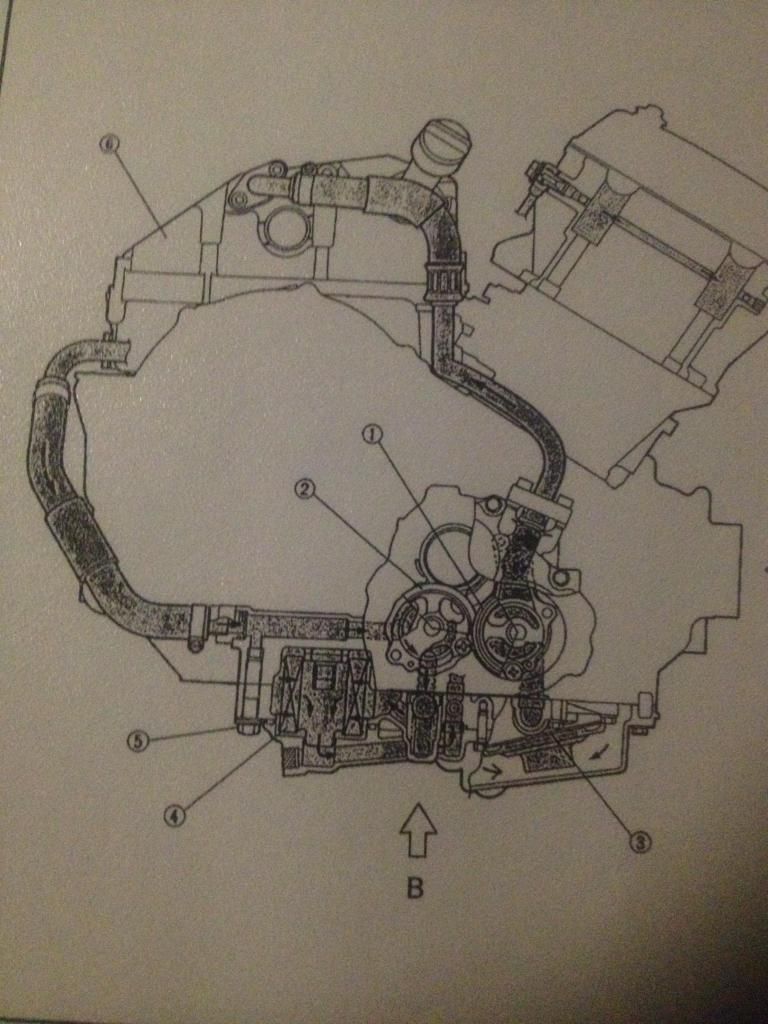

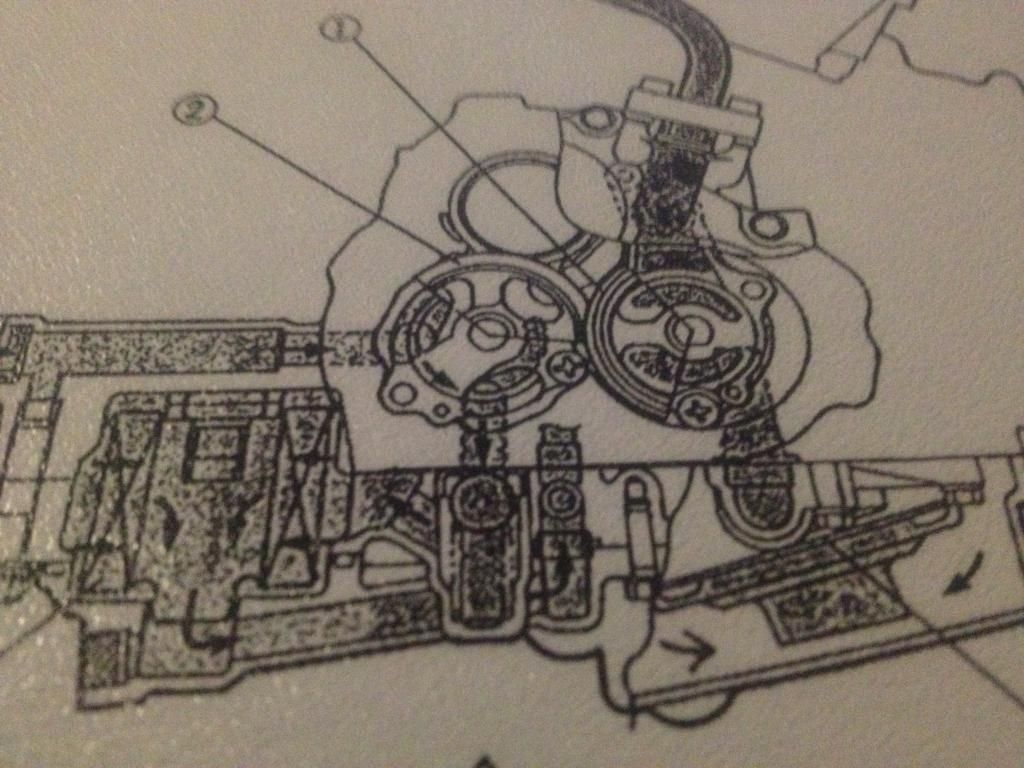

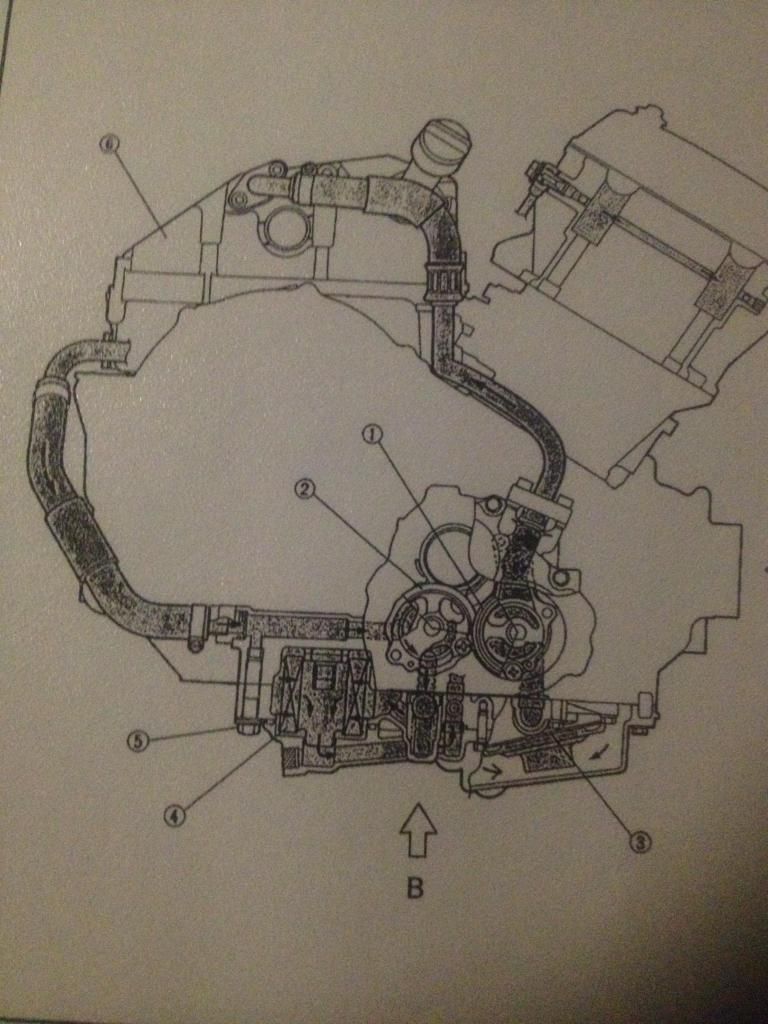

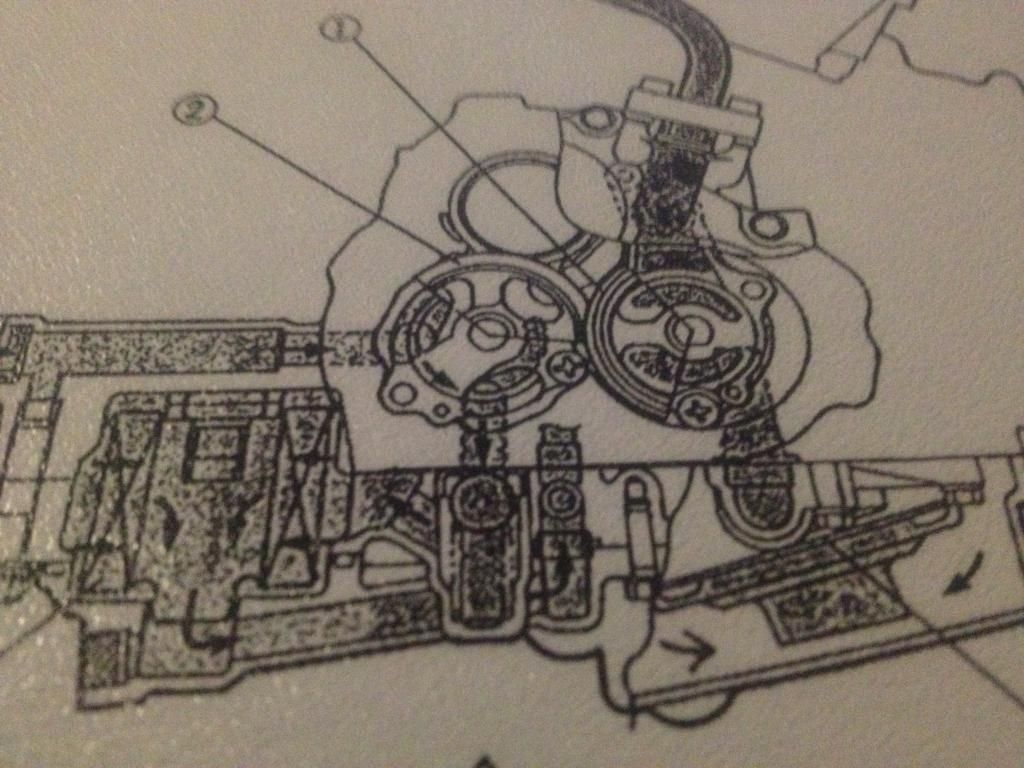

Here is another food for thought,

Priming the motor full of oil before turning it over...

Remove the oil pump sprocket ....

Any reason why I can't use a drill on the oil pump that feeds the motor to pump oil through until it appears at the cams through the I.O. hole instead of feeding oil in through the I.O. in the head???

Anyone done this before????

Priming the motor full of oil before turning it over...

Remove the oil pump sprocket ....

Any reason why I can't use a drill on the oil pump that feeds the motor to pump oil through until it appears at the cams through the I.O. hole instead of feeding oil in through the I.O. in the head???

Anyone done this before????

laughter is the best medicine

- Rod.s

- Site Sponsor

- Posts: 1404

- Joined: Sun Apr 25, 2010 11:01 am

- Location: Brisbane, Australia

Re: 12 - 14mm plug adaptor

cobbadiggabuddyblooo wrote:BOSS BOSS... THE CHAIN THE CHAIN, Is just the connection….

Doesn't this dictate when at TDC, where the cam sprocket sits in relation to the cams and why you need to dial in the cam timing using a slotted hole in the sprocket???

Yes, as per my post, you will realise that the chain is just the connection between the crank and the cams.

TDC is a measurement of crank rotation, the cam timing is in relation to the crank. So the two can be set independently from each other.

As i stated "Assemble as normal with the slotted cam sprockets, bring engine to TDC compression, align cams to the TDC mark and then tighten sprocket bolts"

Surely I wouldn't have any slop with the adaptor screwed into the plug hole and with the plug central to the piston, piston rock would not come into play

Piston rock has nothing to do with the inaccuracies of the piston stop method, the amount of crank rotation whilst the piston is at the top of it stroke is.

If the Yamaha TDC marks are spot on (they are), then using the stop method would only confirm this as an absolute don't you think???

No not quite, see above

If it's not made in China, it's a fake!

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Re: 12 - 14mm plug adaptor

So if the piston stops at 6* btdc and 6* ATDC then 0* may not be 0* on the wheel attached to the crank using the piston stop method.. Correct???

I still can't see why the adaptor won't lock into place as it screws into the plug hole and is used for compression testing???

With a bolt locked into the small hole because of a thread cut and lock nut on the button head, there should be no movement there ?? Correct

I still can't see why the adaptor won't lock into place as it screws into the plug hole and is used for compression testing???

With a bolt locked into the small hole because of a thread cut and lock nut on the button head, there should be no movement there ?? Correct

laughter is the best medicine

- dicky

- Site Sponsor / Administrator

- Posts: 1110

- Joined: Thu Jan 06, 2005 11:26 am

- Location: Ruffy, Victoria.

Re: 12 - 14mm plug adaptor

Cobba,

Picture a sine wave, or even just draw a rough one.

The vertical axis is the height of the piston, the horizontal axis the the rotation of the crank.

You will notice that at the very top and bottom of the vertical axis there is minimal change even though the rotation of the crank is continuing.

This is why the 'bolt in the hole' method is not as accurate.

It is very difficult to tell if you really have TDC.

Aligning the crank directly lets you know for certain that it is at the right position.

Picture a sine wave, or even just draw a rough one.

The vertical axis is the height of the piston, the horizontal axis the the rotation of the crank.

You will notice that at the very top and bottom of the vertical axis there is minimal change even though the rotation of the crank is continuing.

This is why the 'bolt in the hole' method is not as accurate.

It is very difficult to tell if you really have TDC.

Aligning the crank directly lets you know for certain that it is at the right position.

dicky

OOOSDC #5

OOOSDC #5

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Re: 12 - 14mm plug adaptor

Ok thanks for the valued input from you both.

I'm enjoying getting my head around this.

Sine wave was a good analogy to the understanding.

Well at least I'll have a piston stop in amongst the other assortment of tools..

Ok but this differs with the cam lobes because of the shelving on the top of the lobes, so that's why it's done at 1mm lift either side because there is no true TDC reference on the cam lobe like you have on the crank?? Do I get points for this assumption?

The cams are already statically timed on the head so is it easier to fit the camchain inplace by just undoing the sprocket and being mindful not to drop the bolt down into the motor??

All this is being done on a dry run anyhow so once the cam timing is set I should be able to remove the head and barrels and try the 2nd pair of barrels with the Arias pistons.

The head gaskets are the same thickness so i figure i must remove just the cams themselves to place the chain on.

I'm enjoying getting my head around this.

Sine wave was a good analogy to the understanding.

Well at least I'll have a piston stop in amongst the other assortment of tools..

Ok but this differs with the cam lobes because of the shelving on the top of the lobes, so that's why it's done at 1mm lift either side because there is no true TDC reference on the cam lobe like you have on the crank?? Do I get points for this assumption?

The cams are already statically timed on the head so is it easier to fit the camchain inplace by just undoing the sprocket and being mindful not to drop the bolt down into the motor??

All this is being done on a dry run anyhow so once the cam timing is set I should be able to remove the head and barrels and try the 2nd pair of barrels with the Arias pistons.

The head gaskets are the same thickness so i figure i must remove just the cams themselves to place the chain on.

laughter is the best medicine