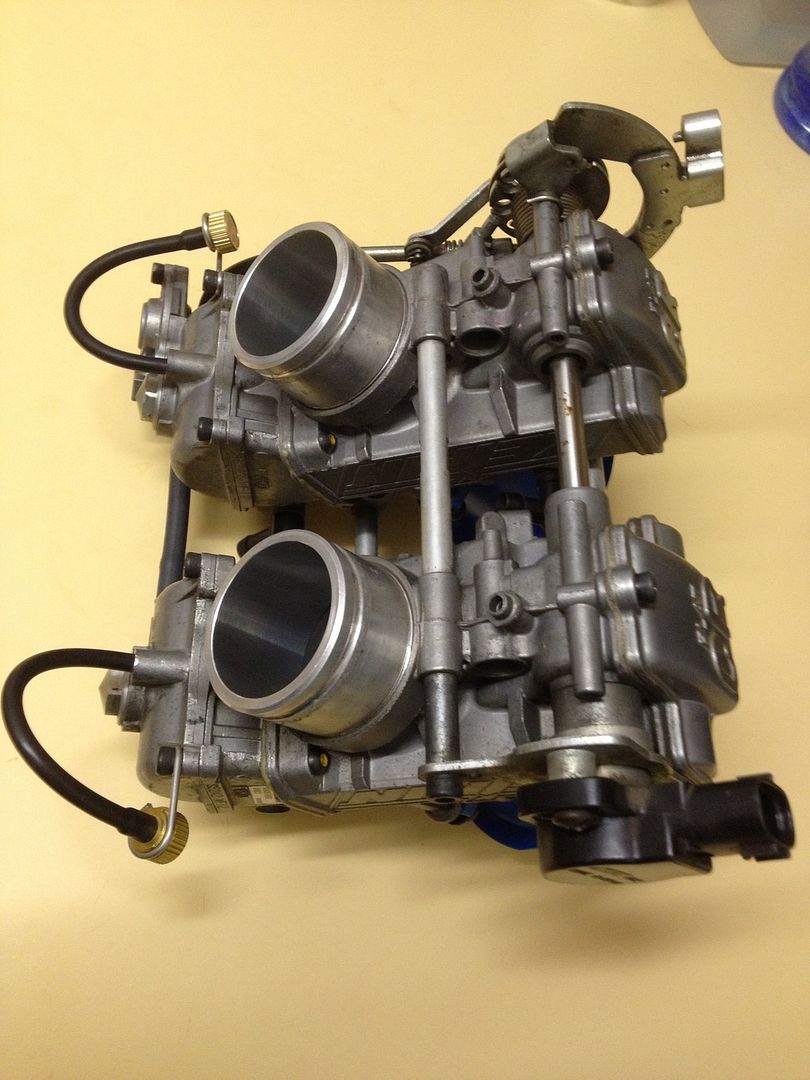

Lifted the cover on the TRX today and decided to finally fit the flex jets into the FCR's.

Removed the float bowls and just had to run a 6mm drill bit through where you access the fuel screws.

The access hole in the fuel bowl just isn't quite wide enough to allow the flex jet to fit.

It's only a poofteenth too small so I placed the 6mm into the drill chuck and rotated the drill by hand to slowly work its way through to avoid any damage to the cast alloy with the hole close to the edge.

Went to fit the 45 pilot jets I ordered but opened the package and Show n Go supplied the wrong jets.

I'll have them in a couple of days to fit in place so in the meantime I'll take the head off and fit another head gasket to gain another couple of points in compression.

Good chance just to check how things look inside. hasn't used any oil even with the 200km's hard riding last track day so good signs

The maths give me 12.5 : 1 up from 12.25 compression with ample valve clearance up my sleeve.