Damn right it is, that's why we ride TRX's!Trixed wrote:The TRX is a pretty cool running engine as is.

If I wanted max HP and min kg I'd buy an R1, but where's the fun in that?

Moderators: trixynut, Mincehead, dicky, phuk72, Jak, Kevtrx849

Damn right it is, that's why we ride TRX's!Trixed wrote:The TRX is a pretty cool running engine as is.

And just as important high flow, not for the bearings but to move the hot oil away from the cylinder head and to the sump for cooling (or oil cooler)Trixed wrote:An air cooled engine would benefit a fair bit from an oil cooler as the oil takes the heat dissipation role to a greater extent than that of a liquid cold engine ie Ducati engines. The TRX is a pretty cool running engine as is.

cobbadiggabuddyblooo wrote:Yes the water cools the top of the motor not the bottom, so the motor is relying on the oil to cool the lower half of the motor.

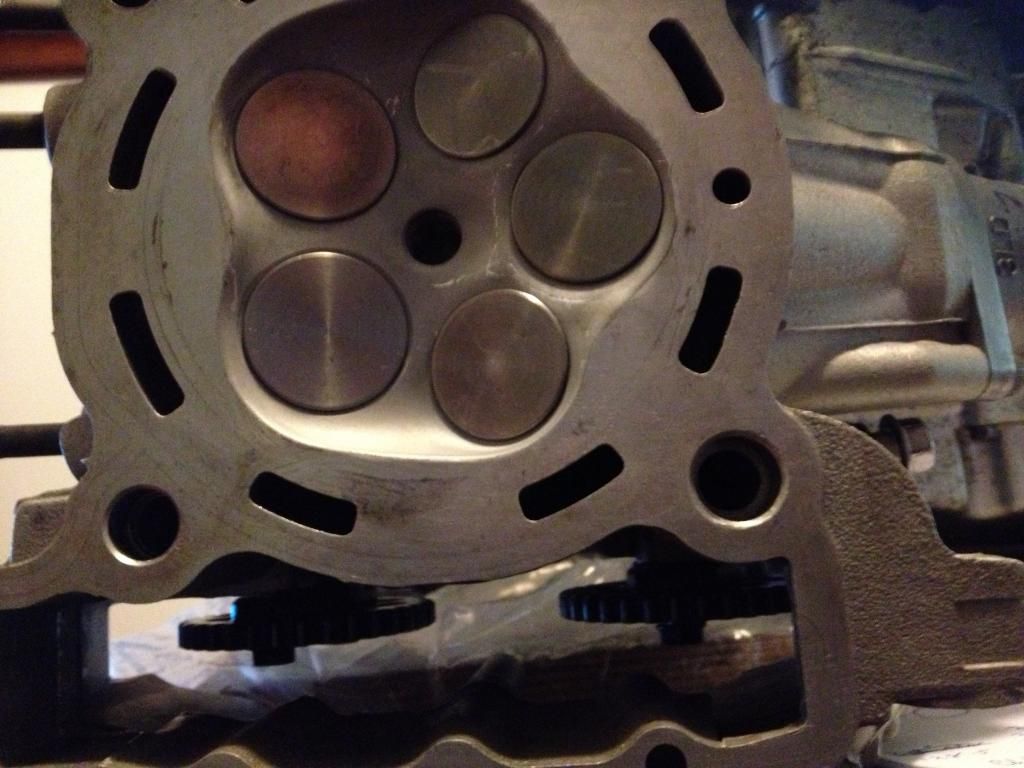

Not quite the full story, water tries to keep a stable temperature in the cylinder head, oil is critical, as it is also used to wick away heat from the head/cams, valves etc, to be cooled in the sump. Over 90% of engine heat is generated in the cylinder head.

The rest of the engine has little requirement for cooling, it runs (without the heat from the head) as cool as a standard car gearbox.

So all cooling is for the benefit of the combustion process.

That includes the clutch, gearbox too.

Another reason why I'm trying a 1 way valve on the engine breather on the current motor.

But that's another story and how this effects inside the crankcases.

As mentioned the oil sender is just a reference point to work from.

Yes I understand your point too Dicky,

no offence but my humorous nature couldn't resist the opportunity mate.

As I mentioned it's all a part of a learning curve for myself and if myself or others learn from what comes out of this, then this thread has served it's purpose.

It's good to see a healthy debate on things I bring up.

Just to clarify

The primary goal here too is not weight loss, it's performance working to enhance each other and if weight loss helps, all the better.

The R1 front end has gained me 2kg, if weight loss was my primary goal, I'd have one of those Spandon alloy frames..

You might want to have a look at the XS650 reed-valve type breather Cobba, most Commandos are now running these beasties. Certainly improve oil loss due to forming a partial vacuum inside the crank-case and there are claims of a horsepower or two gained due to not having to pump crank-case air.cobbadiggabuddyblooo wrote:...Another reason why I'm trying a 1 way valve on the engine breather on the current motor. But that's another story and how this effects inside the crankcases....