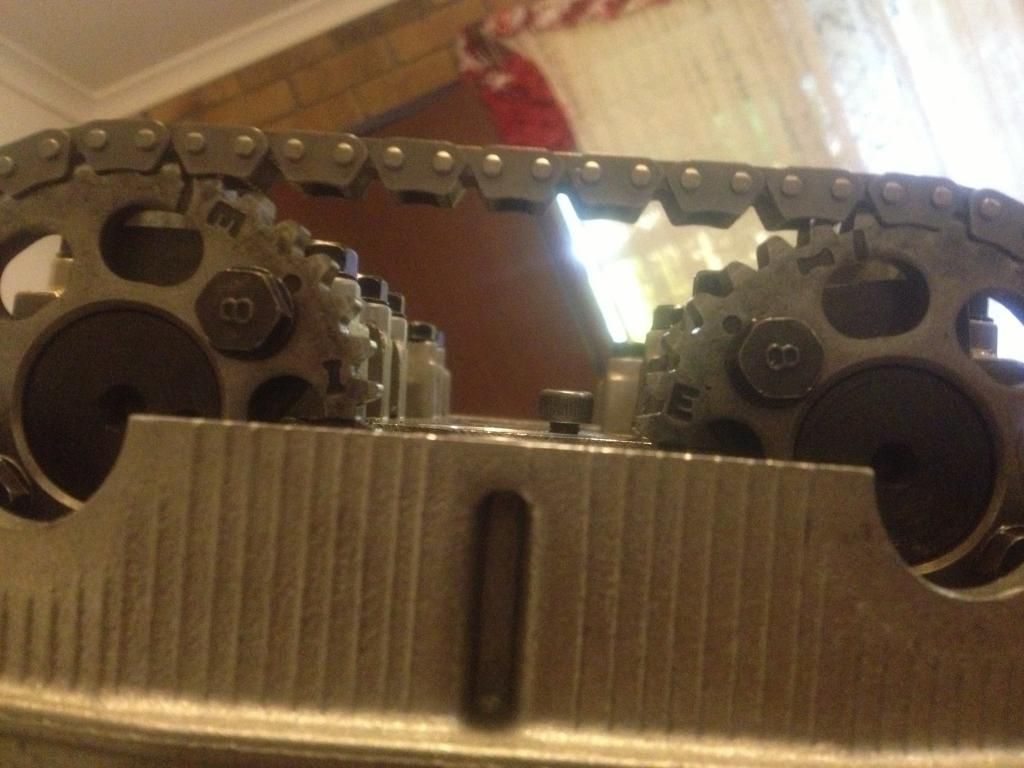

Work bench made up and in the lounge room...perfect I can watch the cricket in the air con...

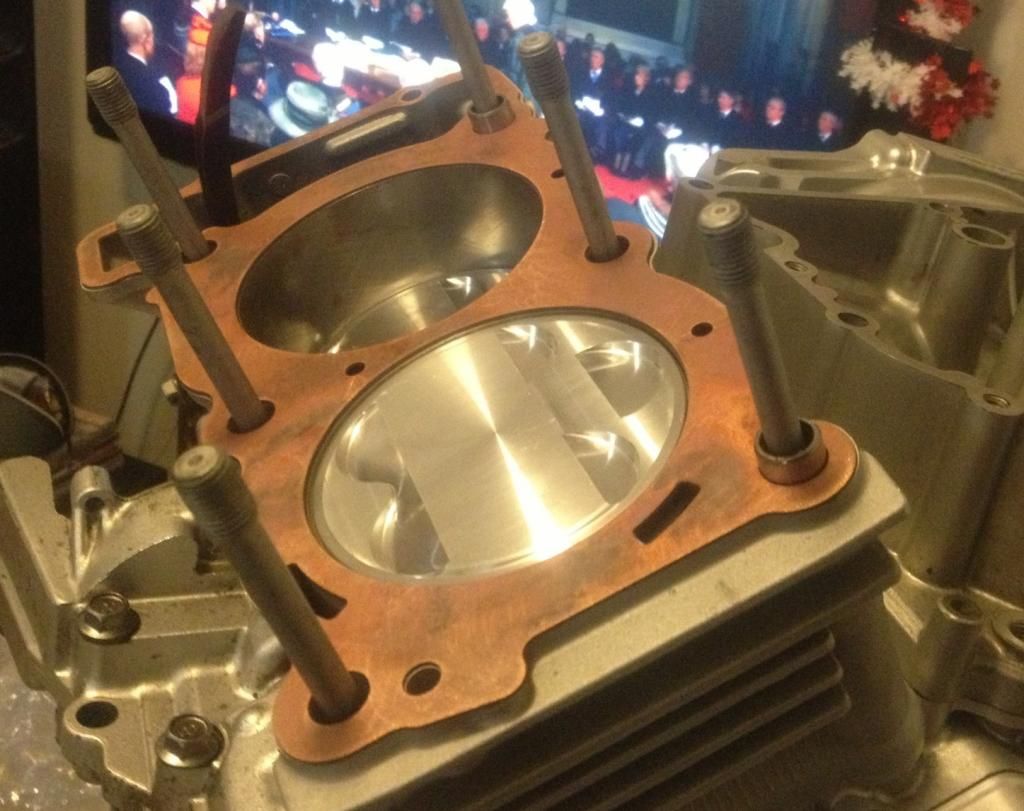

First thing to check with the Arias pistons is the piston deck.

Just with the barrels, base and head gaskets in place I have a 1.55mm clearance and this is using a 0.9mm copper head gasket so I'm feeling confident that once all tensioned down with I'll manage to be above the 0.040" (1mm squish value set by Arias).

I'll mark the valve relief's tomorrow and check they are central to the valve, then place the my head on, rotate the pistons with clay in place and check the squish with the head tensioned up.

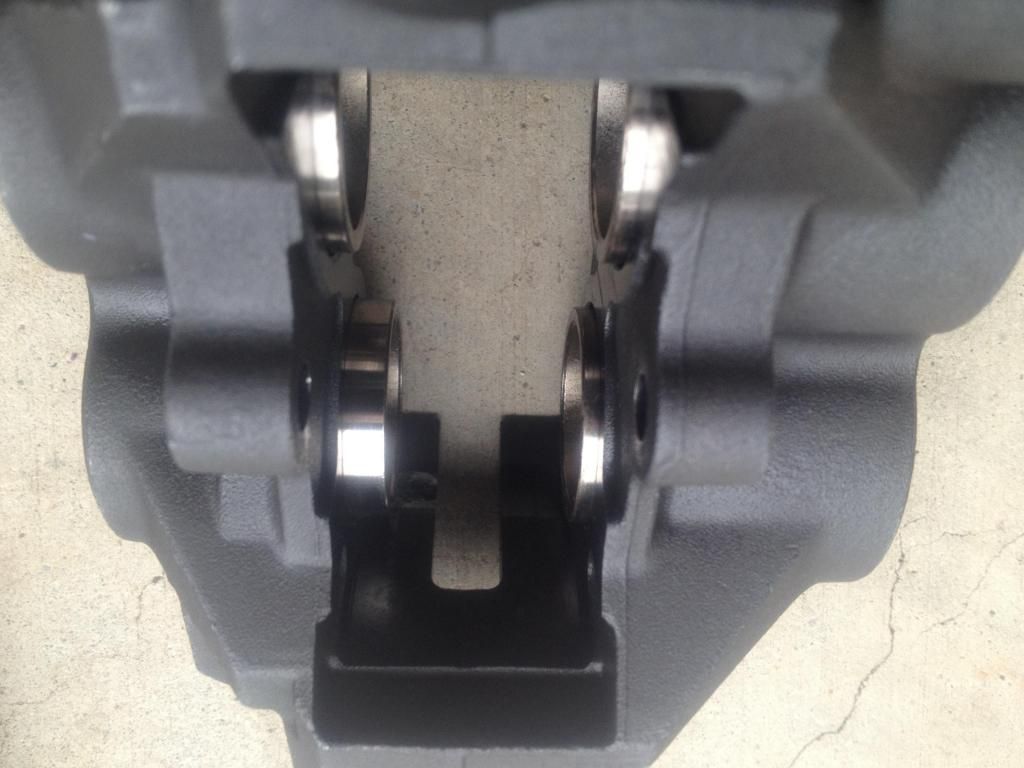

If comfortable, I'll attach the cam chain and gently rotate the crank and check valve clearance and see how things goes.

I took the measurement inline with the wrist pin so no rock will corrupt the measurement taken.

Out of interest I'll take another measurement 90* from the original as a comparison just to see how much the piston movement will effect the measurement..