General Discussion Forum for TRX Enthusiasts...

Moderators: trixynut, Mincehead, dicky, phuk72, Jak, Kevtrx849

-

QuickDraw

- Site Sponsor

- Posts: 165

- Joined: Thu Dec 16, 2010 9:06 am

- Location: Sunshine Coast, QLD

-

Contact:

Post

by QuickDraw » Fri Dec 05, 2014 9:00 pm

I take it you got your rotor off ok Brian?

I remembered what I had to do to get mine off (1st time, reeeeeeally tight!)

http://www.trx850.com/phpBB_forum/viewt ... 1&start=30

It's modified 3-arm gear-puller with a lit bit of bracing to stop the motor turning upside-down

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Post

by cobbadiggabuddyblooo » Sat Dec 06, 2014 10:03 am

Cheers Brett,

I found a puller online and should be here within a week.

Thick round plate type you screw to the rotor and a large threaded centre rod you screw down to press against the crank.

Grabbed a clutch tool too...

Just shopping for a dial guage now...

laughter is the best medicine

-

brockzila

- TRX-Enthusiast

- Posts: 348

- Joined: Mon Feb 18, 2008 2:30 pm

Post

by brockzila » Sat Dec 06, 2014 11:03 am

It's called a harmonic ballancer puller. It's the kind of tool not many people have.

Is it Brock friendly???

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Post

by cobbadiggabuddyblooo » Sun Dec 07, 2014 1:55 am

dandywarhol wrote:I was always under the impression that the crank webs were the equivalent of the piston and 33% of the rod weight for dynamic balance..................

Add you Piston weight plus reciprocating mass of the Conrod.

Next, Take 50% of this measurement

Then add that to the rotating mass of the con rod plus the weight of the bearings plus oil weight and that's your bob weight. (28.5 g for trx bearing and oil)

The 270* crank rotates smoother hence the 50% balance factor, much the same as a v8 crank.

Different motor configurations though may work better with a 65% bob weight like earlier model Nortons with a 360* crank.

laughter is the best medicine

-

dandywarhol

- Site Sponsor

- Posts: 1639

- Joined: Fri Nov 24, 2006 12:56 pm

- Location: Edinburgh, Scotland

Post

by dandywarhol » Sun Dec 07, 2014 12:34 pm

Interesting. That's why I thought it was accepted to be 33% of the conrod mass - difficult to calculate the reciprocating mass of the rod when the small end barely reciprocates compared to the big end.

I still reckon it very much suck it and see on a piston engine - so many factors to take into when balancing, including the "crossplane" design of the 270/90 crank and the fact the piston travels further during the first 90 degrees of crank rotation than the last 90 deg. of the stroke. Now, if it was a rotary..........................

1996 TRX 850, blue, Ohlins 46HRCLS, Race Tech Gold Valves, 0.90 springs, Venom pipes, R6 brakes............

1974 Yamaha RD250A, Candy Blue

1998 Yamaha SZR660, blue of course

1967 Yamaha TD1C 250, Blue and white

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Post

by cobbadiggabuddyblooo » Sun Dec 07, 2014 4:12 pm

33% may be a bit off the ballpark in this case of the TRX as both the carrillo and OEM rod are around the 28% mark

Carrillo rod being 111/300 .... 111 grams being 27% of 411grams

oem rod being 137/330 ..... 137 grams being 29% of 467grams

Reference for those not knowing what we are dribbling over..

Reciprocating relating to the up n down motion within the bore (small end) and rotating mass being rotating around the crank (big end) of the con rod.

But as you said, these figures change as each style of motor has it's own characteristics in stroke, configuration and overall design to factor in.

laughter is the best medicine

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Post

by cobbadiggabuddyblooo » Tue Dec 09, 2014 11:27 am

Dropped the exhaust system off today to have it ceramic coated and went to Serco at Desion st at the Gabba and handed them the Arias pistons and spare barrels for boring.

Looking at the valve reliefs on the Arias pistons, they look like they can easily accommodate the 1mm oversize valves so I'll do a dry run and dial in the cams.

So in two minds weather to continue the original build with the Ross pistons and rebuild the spare motor in the bike with the 878 pistons or just do 1 rebuild and rebalance the crank and offload the spare motor with the new std rods I have still in the box and the Ross pistons and barrels .

At least I can check clearances on the Arias pistons before making a decision.

Dumped the oil yesterday on the spare motor and all was good after 6000km on synthetic oil.

I used 1 litre of oil in 5000km, very little metal reflections looking at the oil in the sun and only minor discolouration from blow by.

Testament to Kev and his regular servicing on this one. He purchased the bike new and 140,000km now clocked up, there is plenty of life left in it.

laughter is the best medicine

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Post

by cobbadiggabuddyblooo » Thu Dec 18, 2014 6:18 am

Picked up the exhaust after having it ceramic coated inside and out.

Nice finish so be interested to see how easy it will be able to keep this clean.

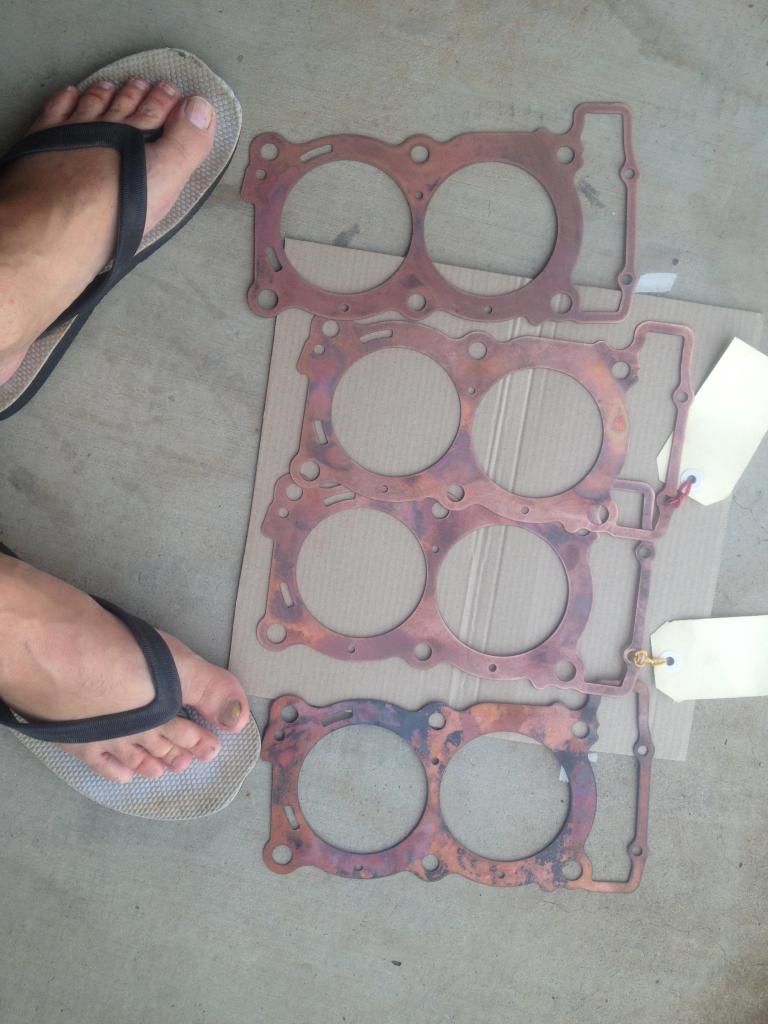

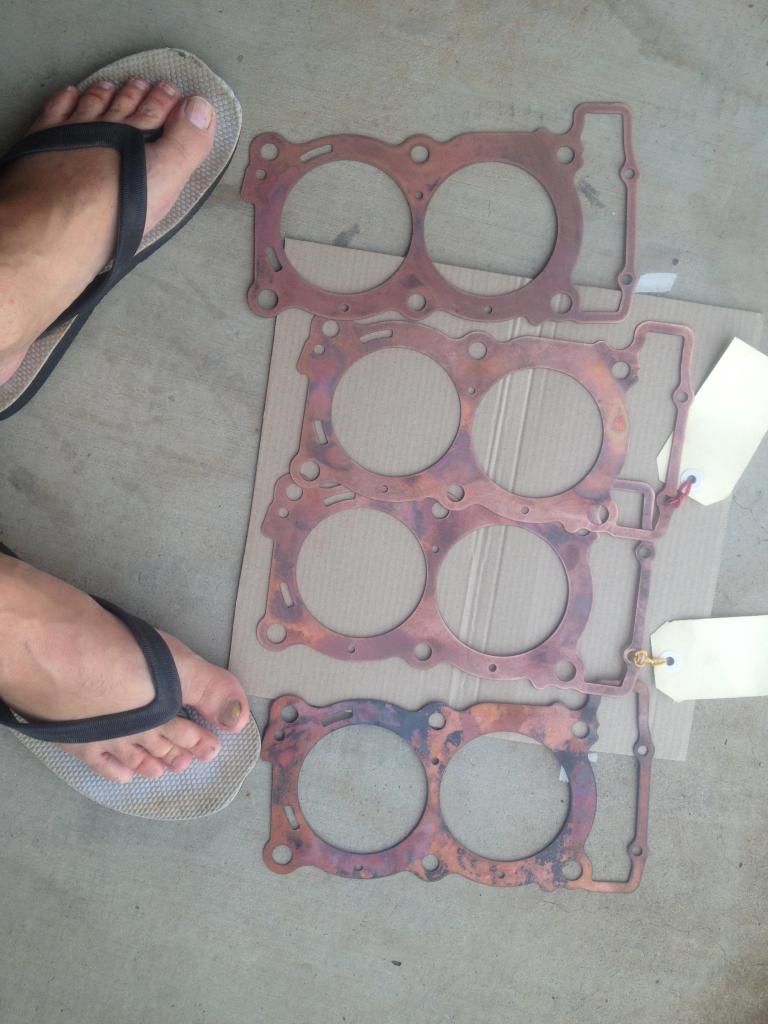

Got a call on the way and the copper head gaskets I had ordered where ready for pick up too.

Cleaned the discs up and new pads arrived today too and things where looking good to get a ride in before Xmas but when I was about to remove the front wheel and clean the callipers, I found a pool of oil at the base of the calliper mount...

Dammm Fork seal is weeping ...

laughter is the best medicine

-

Con Rod

- Site Sponsor

- Posts: 1126

- Joined: Wed Nov 16, 2011 11:48 pm

- Location: Sydney, Australia

Post

by Con Rod » Thu Dec 18, 2014 7:55 am

I see you have a bung for an O2 sensor, very nice. Makes tuning a lot easier.

Did you get those pipes made up?

Paul

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Post

by cobbadiggabuddyblooo » Thu Dec 18, 2014 8:37 am

No just a Akrapovic system I modded with a bung in each header.

Rod has a pair of O2 sensors so the plan is to use a camera to film both sensors and I'll mark the throttle so we can see a response under load out on a ride.

Next mission though, Danny just contacted me and I'll slip his head with the valves removed onto the 878 barrels and double check the valve reliefs are central on the Arias pistons.

This will give me an idea if there already is enough clearance in the valve reliefs for the 1mm oversize valves..

laughter is the best medicine

-

Rod.s

- Site Sponsor

- Posts: 1404

- Joined: Sun Apr 25, 2010 11:01 am

- Location: Brisbane, Australia

Post

by Rod.s » Thu Dec 18, 2014 8:52 am

ooooh shiny bits

If it's not made in China, it's a fake!

-

cobbadiggabuddyblooo

- Site Sponsor

- Posts: 6809

- Joined: Thu Aug 28, 2008 9:19 am

- Location: Brisbane,Australia

Post

by cobbadiggabuddyblooo » Thu Dec 18, 2014 9:49 am

Good investment I feel for $150 to coat inside and outside.

How is the exhaust on the chookie Rod since you coated yours????

I'm sure it would cost about half that to just have them polished up.

laughter is the best medicine

-

Rod.s

- Site Sponsor

- Posts: 1404

- Joined: Sun Apr 25, 2010 11:01 am

- Location: Brisbane, Australia

Post

by Rod.s » Thu Dec 18, 2014 10:29 am

cobbadiggabuddyblooo wrote:Good investment I feel for $150 to coat inside and outside.

How is the exhaust on the chookie Rod since you coated yours????

I'm sure it would cost about half that to just have them polished up.

It would cost you more than that to polish up the TRX headers….i know

If it's not made in China, it's a fake!

-

Con Rod

- Site Sponsor

- Posts: 1126

- Joined: Wed Nov 16, 2011 11:48 pm

- Location: Sydney, Australia

Post

by Con Rod » Thu Dec 18, 2014 11:21 am

anyone priced up getting a set made?

Kayla's, while very nice are AU$850, delivered at the moment, ad a decent can and its well over $1000. Given a full Akro system for the MT07 is $850 delivered I should think it might be more economical to get a 2 into 1 made locally.

Paul

-

Rod.s

- Site Sponsor

- Posts: 1404

- Joined: Sun Apr 25, 2010 11:01 am

- Location: Brisbane, Australia

Post

by Rod.s » Thu Dec 18, 2014 11:40 am

Con Rod wrote:anyone priced up getting a set made?

Kayla's, while very nice are AU$850, delivered at the moment, ad a decent can and its well over $1000. Given a full Akro system for the MT07 is $850 delivered I should think it might be more economical to get a 2 into 1 made locally.

They are really easy to get made…..but quite hard to get made correctly and to take advantage of the 270/90 crank, that is why Akro systems are sort after, they have done all the hard work on a dyno for you and they guarantee it will work

If it's not made in China, it's a fake!