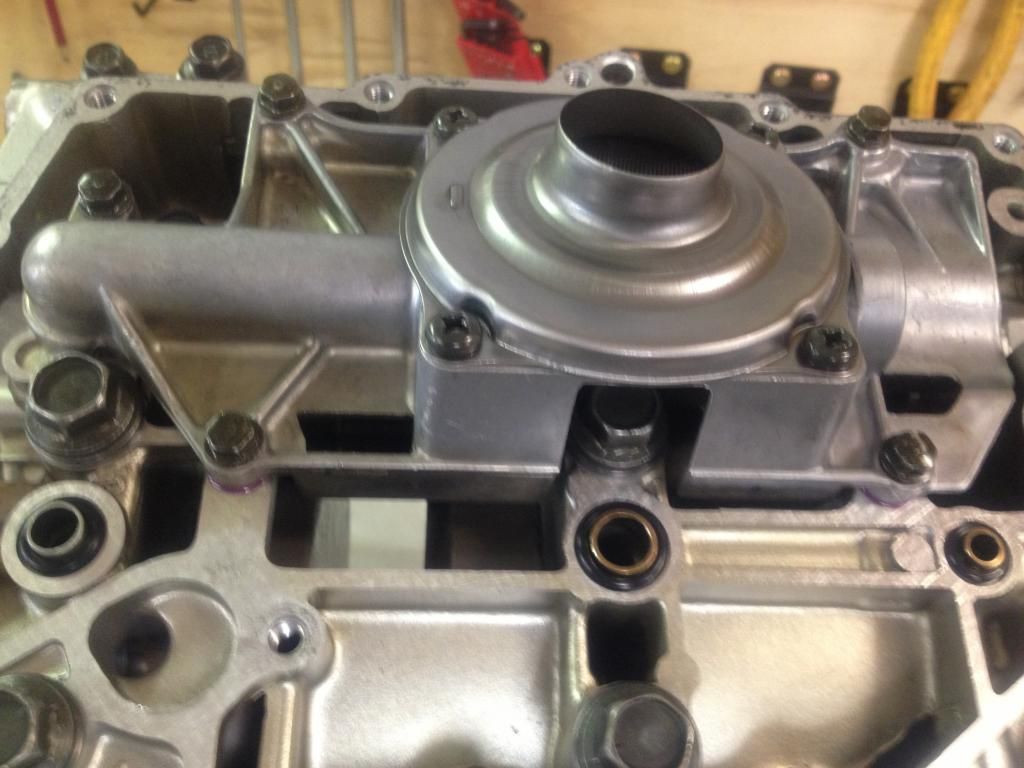

After 18 months I finally picked up the head n barrels all completed this arvo.

A text at 2.10am this morning from John to tell me all is finally ready to be picked up.

Seems that he has been on salary from Yamaha this last 12mths and he's been doing 12-18hr days .

Finishes at the shop and then over to work on the Yamaha race team bikes till all hours.

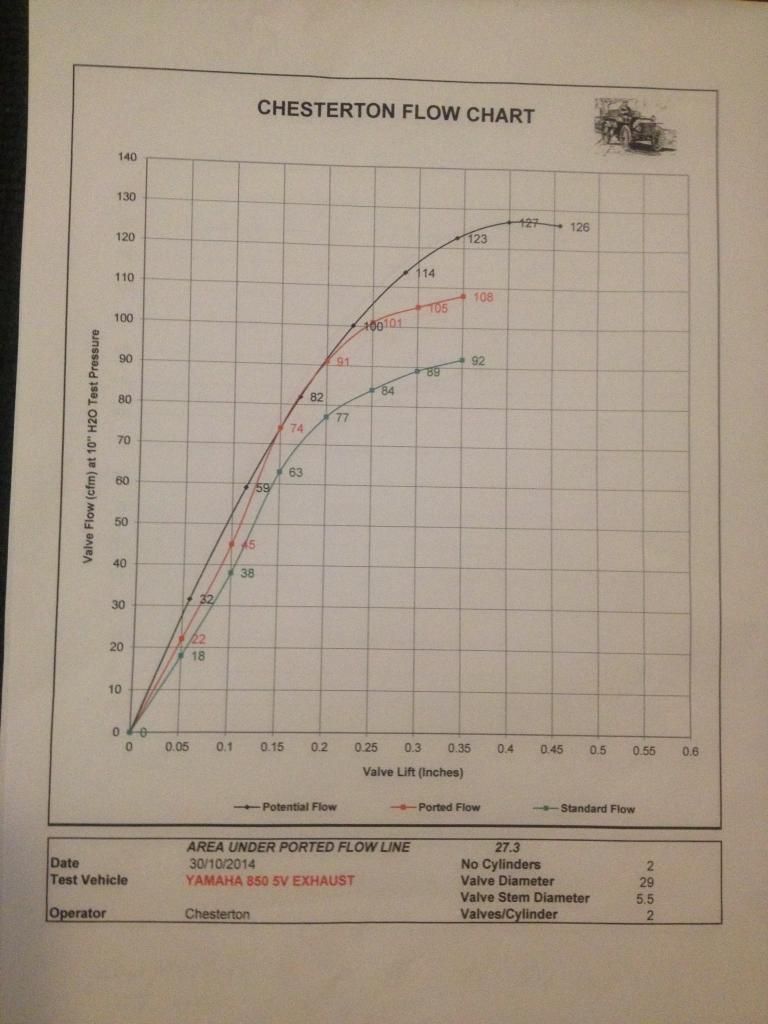

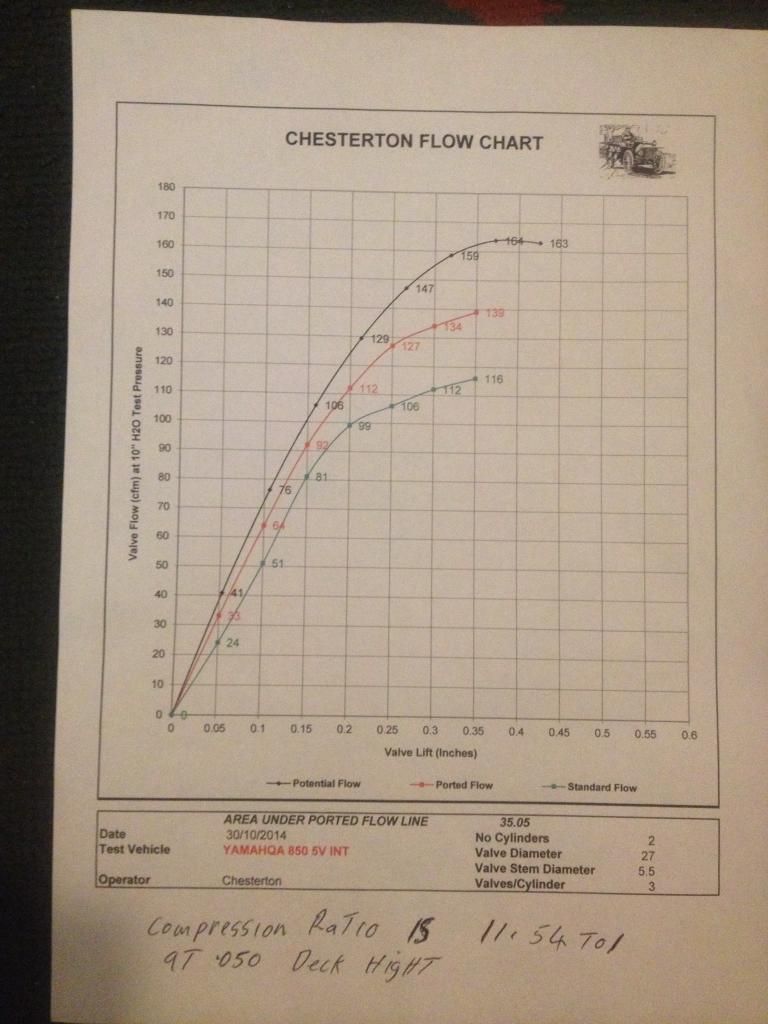

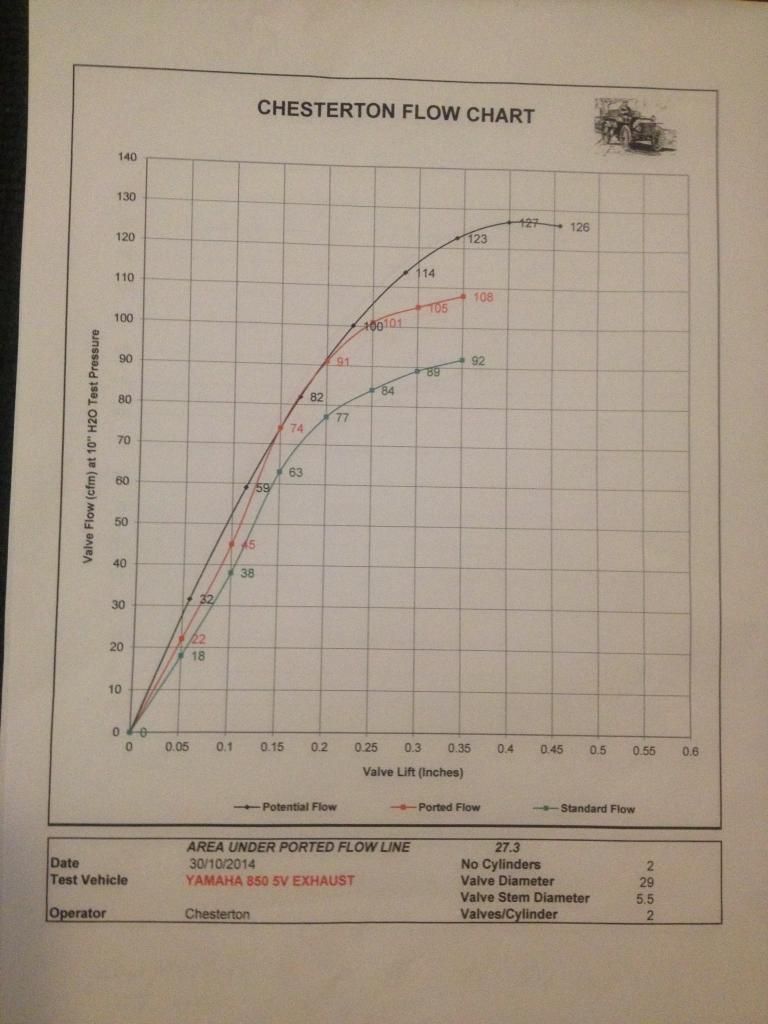

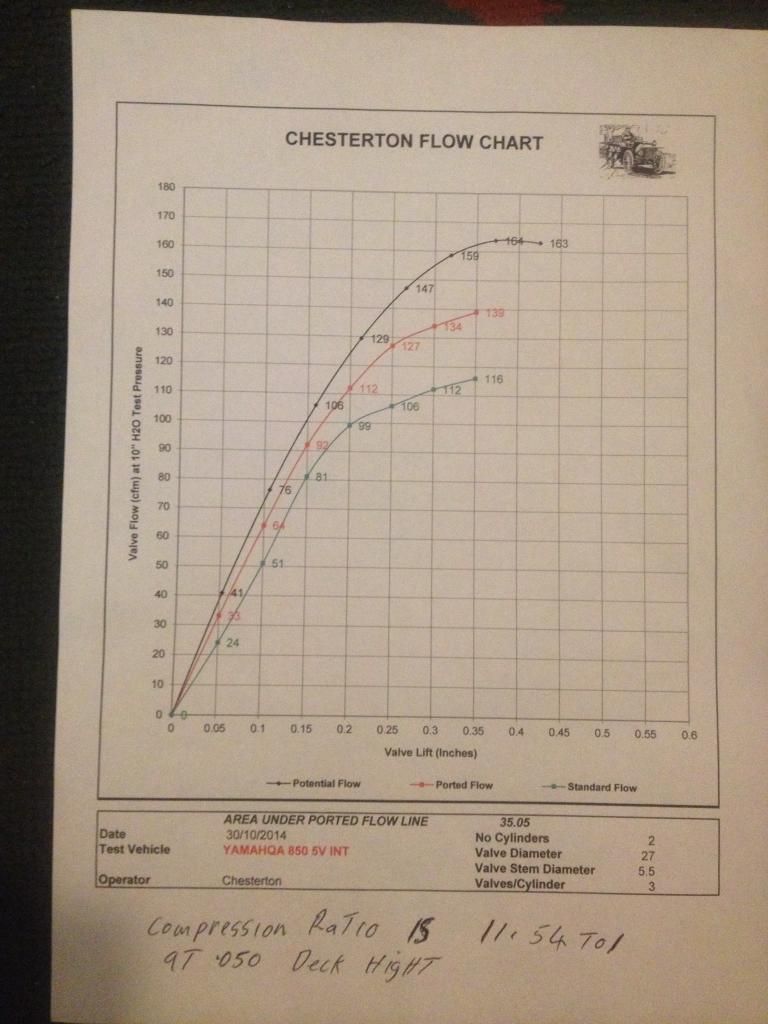

He handed me the flow charts from the head with a set of Mark's 1mm oversize valves and Kent cams.

The green line is the head in original form

The red line is with the 1mm oversize valves and flow work.

The black line is optimum flow(ideal world with a cylindrical port falling straight onto the valve with no bend ),

But as he pointed out this is pretty much unreachable because the TRX port curves down onto the valve, the more flow the less efficient the bottom side of the port becomes hence the more D shaped port with a flat bottom to aid the flow.

So i'm up from 92cfm to 108cfm on the EXHAUST ports with close to optimum around half lift.

Again on the inlet gains from 116cfm to 139cfm and finding myself ever closer to optimum till just after half lift.

Final compression ratio of 11.54:1 with the std 1mm gasket and a deck height of just over 1mm (0.050")

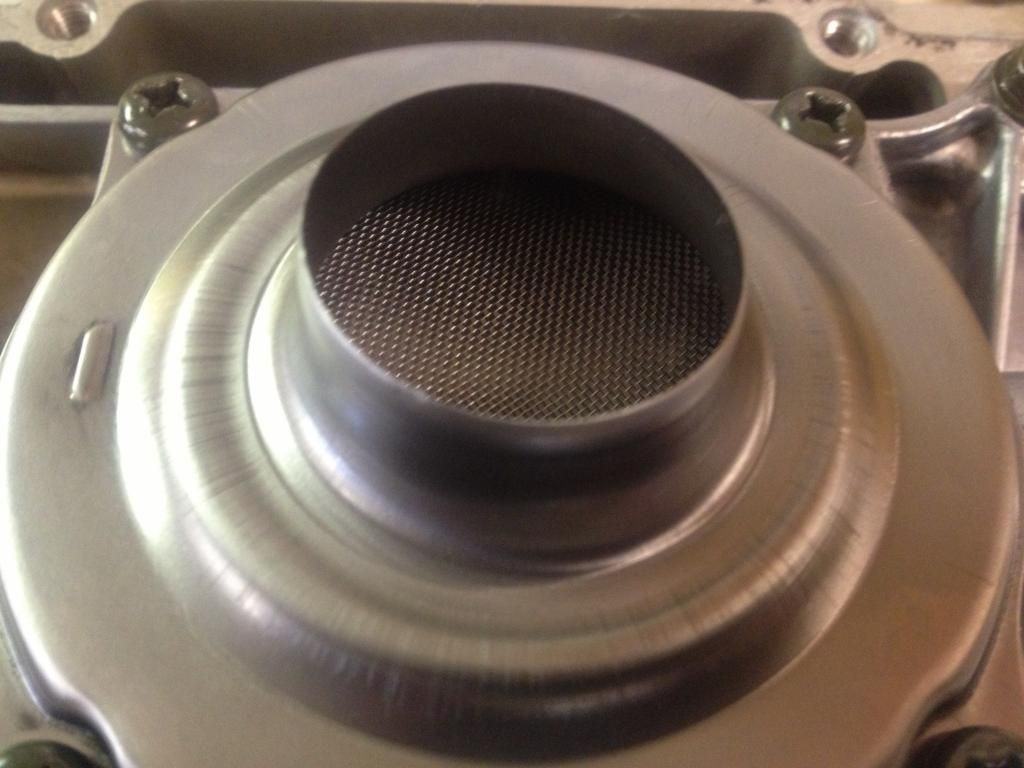

All the valves springs have been shimmed so correct lengths to achieve optimum pressure and no binding.

There is clearance so there will be no contact between the valves just incase i give it a bit of a rev if I hit a neutral and at 0.050" deck height there will be enough clearance to avoid touching the valve pockets in the piston.

When I mentioned on having copper head gaskets made up , he agreed on the benifits with a copper head gasket and hollimer spray to seal it all off. John made me aware of the compression gains in contact with the copper gasket and the steel ring from the bore.

Advice on going under the 0.50" squish was maybe 0.048" but wouldn't really want to go down much more as you start to loose the integrity and margin for error.

Again to improve the flow a little more ,options open like decreasing valve stem size again lower the integrity and you get a little more waggle or movement .

Was it worth the wait, I feel pretty confident and the support is there to question him if need be for advise.